Selection of location

Layout of poultry farm

A small size poultry farm doesn’t require any special layout as it involves construction of only one house. The medium and large size farms require special considerations for placement of building in the farm premises. The basic principles to be observed for layout are

Different types of poultry houses

Optimal environmental conditions for rearing broilers

Temperature - 22-300C (70-850F)

Relative Humidity - 30-60 %

Ammonia level - Less than 25 ppm

Litter moisture - 15-25%

Air flow - 10-30 metres/minute

House Orientation (Direction)

The poultry house should be located in such a way that long axis is in east-west direction. This will prevent the direct sunshine over the birds.

Size

Each broiler require one square foot of floor space while a layer requires two square feet of floor space under deep-litter system of rearing. So the size of the house depends on the number of birds to be reared.

Length

The length of the house can be of any extent. The number of birds reared and availability of the land determines the length of poultry house.

Width

The open sided poultry houses in tropical countries should have a width not more than 22 to 25 feet in order to allow ample ventilation and aeration at the mid-portion. Sheds wider than this will not provide adequate ventilation during the hot weather. If the width of the shed is more than 25 feet, ridge ventilation at the middle line of the roof top with proper overhang is a must. Hot air and obnoxious gases which are lighter than air move upward and escape through ridge ventilation. In environmentally controlled poultry houses, the width of the house may be even 40 feet or more since the ventilation is controlled with the help of exhaust fans.

Height

The height of the sides from foundation to the roof line should be 6 to 7 feet (eaves height) and at the centre 10 to 12 feet. In case of cage houses, the height is decided by the type of cage arrangements (3 tier or 4 tier).

Foundation

Good foundation is essential to prevent seepage of water into the poultry sheds. The foundation of the house should of concrete with 1 to 1.5 feet below the surface and 1 to 1.5 feet above the ground level.

Floor

The floor should be made of concrete with rat proof device and free from dampness. The floor of the house should be extended 1.5 feet outside the wall on all sides to prevent rat and snake problems.

Doors

The door must be open outside in case of deep-litter poultry houses. The size of door is preferably 6 x 2.5 feet. At the entry, a foot bath should be constructed to fill with a disinfectant.

Side walls

The side wall should be of 1-1.5 feet height, and generally at the level of bird’s back height. This side wall protects the bird during rainy days or chill climate and also provides sufficient ventilation. In case of cage houses, no side wall is needed.

Roof

The roof of the poultry house may be thatched, tiled, asbestos or concrete one depending upon the cost involvement. Different types of roofs are Shed, Gable, half-monitor, full-monitor (Monitor), Flat concrete, Gambrel, Gothic etc. Gable type is mostly preferred in tropical countries like India.

Overhang

The overhang of the roof should not be less than 3.5 feet in order to prevent the entry of rain water into the shed.

Lighting

Light should be provided at 7-8 feet above the ground level and must be hanged from ceiling. If incandescent bulbs are used, the interval between two bulbs is 10 feet. In case of fluorescent lights (tube lights) the interval is 15 feet.

Poultry can be housed under different systems based on following factors,

Broadly, poultry housing systems are classified into three systems:

1) Free range system

This system is adopted only when adequate land is available to ensure desired stocking density by avoiding overcrowding. We can rear about 250 adult birds per hectare. A range provides shelter, greens, feed, water and shade. Foraging is the major source of feeding for birds. Shelter is usually provided by temporary roofing supported by ordinary poles. The fields are generally used on rotational basis after harvesting of crops by moving of birds from one field to another depending on cropping programme. All categories of birds can be reared in this system. This system is most preferred for organic egg production.

Advantages

Disadvantages

2) Semi-intensive system

As the name indicates birds are half-way reared in houses and half-way on ground or range, i.e. birds are confined to houses in night or as per need and they are also given access to runs. The houses are with solid floors while runs are fields only. The success of rearing depends on maintenance of condition of runs to reduce the contamination. Runs can also be used on turn basis. The stocking density rate on an average for adult birds is 750 per hectare. This system is usually adopted for duck rearing. The feeding and watering facilities are provided in the pen.

Advantages

Disadvantages

3) Intensive system

Birds are totally confined to houses either on ground / floor or on wire-netting floor in cages or on slats. It is the most efficient, convenient and economical system for modern poultry production with huge numbers.

Advantages

Disadvantages

In this system the birds are kept inside the house all the time. Arrangement for feed, water and nest are made inside the house. The birds are kept on suitable litter material of about 3” to 5” depth. The word litter is used for fresh litter material spread on the floor. Usually paddy husk, saw dust, ground nut hulls, chopped paddy straw or wood shavings are used as litter materials. This arrangement saves labour involved in frequent cleaning of faecal matter (droppings), however it needs periodical stirring. The litter is spread on the floor in layers of 2” height every fortnightly till the required is achieved.

Advantages

Disadvantages

The built up litter

Deep litter or built up litter is accumulation and decomposition of litter material and excreta until it reaches a depth of 8” to 12”, after an original start of 3” to 5” depth. Bacterial action decomposes litter and excreta into crumble form and heat is produced during decomposition which keeps litter dry and warm. If the amount of droppings exceeds the litter, fresh litter will be added to lower the amount of droppings. Periodical stirring of the litter should be carried out for an effective functioning of built-up litter. After one year, the litter is changed and the decomposed litter is used as good quality manure. The best built-up litter should be dry, friable and free from obnoxious odour.

In a slatted floor, iron rods or wood reapers are used as floor, usually 2-3 feet above the ground level to facilitate fall of droppings through slats. Wooden reapers or iron rods of 2” diameter can be used on lengthwise of the house with interspaces of 1” between rods.

Advantages

Disadvantages

This system is commonly practiced for rearing birds for hatching eggs production, particularly meat-type breeders. Here, a part of the floor area is covered with slats. Usually, 60% of the floor area is covered with slats and rest with litter. Feeders and waterers are arranged in both slat and litter area. In case of breeder flock, nest boxes are usually kept on litter area.

Advantages

Disadvantages

This system involves rearing of poultry on raised wire netting floor in smaller compartments, called cages, either fitted with stands on floor of house or hanged from the roof. It has been proved very efficient for laying operations, right from day-old to till disposal. At present, 75% of commercial layers in the world are kept in cages. Feeders and waterers are attached to cages from outside except nipple waterers, for which pipeline is installed through or above cages. Auto-operated feeding trolleys and egg collection belts can also be used in this rearing system. The droppings are either collected in trays underneath cages or on belts or on the floor or deep pit under cages, depending on type of cages.

Advantages

Disadvantages

Types of cages

Based on the number of birds in a cage, it is classified as

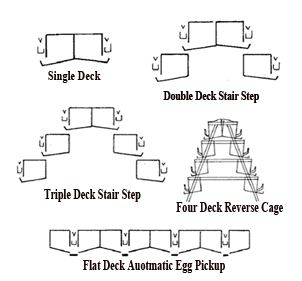

Based on the number of rows

Based on arrangement of cages

1) Stair-step cages

a) M-type cages

b) L-type cages

2) Battery cages (Vertical cages)

Based on the type of bird reared

Broiler cages

1) Brooder cage / chick cage

|

Brooder cage |

Specifications: Front feeding length : 60 inch

Front & Back height : 12 inch

Depth : 36 inch

No. of chicks (0-8 weeks) accommodated per box : 60

Chick cages are arranged either as single deck or double deck system. The feeders and waterers are arranged on outside. Now-a-days nipple drinker system is followed from day-old itself. Newspaper may be spread over the cage floor for first 7 or 10 days. Feed is usually provided inside the cage during the first week of age.

2) Grower cage

|

|

Grower cage |

Grower cage |

Specifications: Front feeding length : 30 inch

Front & Back height : 15 inch

Depth : 18 inch

No. of growers (9 to 18 weeks) accommodated per box : 10

3) Layer cage

Two types of stair-step layer cages are commonly used in open-sided poultry houses

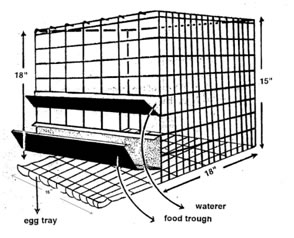

a).Conventional cages

Specifications for each box: Front feeding length : 15 inch

Front height : 18 inch

Back height : 15 inch

Depth : 18 inch

b).Reverse cages

Specifications for each box: Front feeding length : 18 inch

Front height : 18 inch

Back height : 15 inch

Depth : 15 inch

These cages can hold 3 to 4 birds. They are arranged either in 2-tier or 3-tier. A slope of 1/6 is provided in conventional cages, where as in reverse cages the slope is 1/5.

Advantages of reverse cages over conventional cages

Elevated cage layer house

The height of the shed is raised by 6-7 feet using concrete pillars. The distance between two pillars is 10 feet. Two feet wide concrete platforms are made over the pillars. When 3 ‘M’ type cages are arranged 4 platforms are needed. In case of 2 ‘M’ and 2 ‘L’ type cages are arranged 3 platforms are needed. When constructing platforms projecting angles or iron rods to be provided to fix the cages. The inter-platform distance is 6-7 feet depending upon the type of the cages used. The total height of the house is 20-25 feet and the width is 30-33 feet. This type of houses provides sufficient ventilation in tropical countries.

Floor space requirements

Type |

Age |

Deep-litter |

Cages |

Egg-type chicken |

0-8 |

0.60 |

0.20 |

9-18 |

1.25 |

0.30 |

|

>18 |

1.50 |

0.50 |

|

Meat-type chicken |

0-4 |

0.30 |

- |

4-8 |

0.75 |

- |