Farm Implements

Tillage Implements

a. Disc Plough

Special Features |

It is used for primary tillage and is especially useful in hard and dry, trashy, stony or stumpy land conditions and in soils where scouring is a major problem |

|---|---|

Specification |

Number of furrows : 2-4 |

Top of page

Top of page

b. Cultivator

Special Features |

It is used for seed bed preparation both in dry and wet soils. It is also used for interculture purpose and puddling purposes |

|---|---|

Specification |

Type : Tractor mounted |

Top of page

Top of page

c. Rotavator

Special Features |

It is used in dry as well as wet land cultivation |

|---|---|

Specification |

Type : Tractor mounted |

Top of page

Top of page

d.Mould Board Plough

Special Features |

Suitable for primary tillage in canal irrigated or heavy rain areas where too much weeds grow.Completely invert and pulverize the soil, uproot all weeds, trash and crop residues and bury them under the soil |

|---|---|

Specification |

1. Model MT-02 (M) 2. Max. Depth 22 cms 3. Working width 85 cms 4. Weight 225 kg 5. Tractor Compatibility 35 to 55 HP |

Top of page

Top of page

Sowing Implements

a.Improved Broad Bed Former cum Seeder

Special Features |

|

|---|---|

Specification |

Overall dimension : 2020 x 2050 x 1100 mm |

General information:

The implement will form broad beds separated by furrows and simultaneously undertake sowing in rows on the bed formed. The unit can be hitched to the 3 point linkage of tractor. This unit consists of a sheet metal float which forms the broad beds separated by furrows at an interval of 160 cm. Over the sheet metal frame, seed hoppers and cup feed seed metering mechanism are provided. The drive for the seed metering device is taken from a projecting spoke type ground wheel which trails behind the furrow openers, on the bed. The furrow openers are made of cultivator shovels provided with wings. The depth of furrow opener can be adjusted with respect to bed surface.

Top of page

Top of page

b.Broadcaster

Special Features |

Uniform distribution of seeds. |

|---|---|

Specification |

Type : Manually operated |

General Information:

The centrifugal type unit that is hung in front of the operator is used to broadcast seeds and granular fertilizers by rotating the handle. The material is put in the hopper in batches of 3 to 5 kg and the operator has to walk while rotating the handle. The material is spread over a 3.5 to 10 m width.

Top of page

Top of page

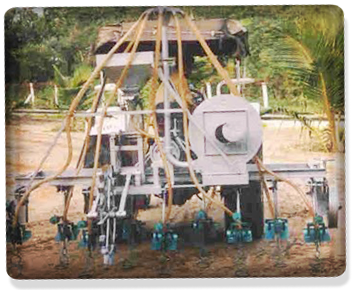

c.Tractor drawn Air Assisted Seed Drill

Special Features |

|

|---|---|

Specification |

Type : Tractor mounted |

General Information:

The unit consists of an air blower and drive, seed hopper and feeding device, seed distributor head, seed tubes, furrow opener ground wheel and furrow closer. The above components mounted on a 9 tyne cultivator. Blower is used to blow air through a vertical distributor tube to the distributor head. Seed is metered by the ground wheel into the air stream in controlled manner. The stream of seed is distributed to the 9 furrow openers by the distributor head. This ensures uniform drilling of fine seeds.

Top of page

Top of page

d.Birsa Animal Drawn Seed Drill

Special Features |

|

|---|---|

Specification |

Type : Bullock drawn |

General Information:

In this machine, seeds are dropped by a rubber agitator and silt hole while the fertilizer is dropped manually using the funnel provided for that purpose. Only the ground wheel drives the agitator for the seeds and a small ridger type furrow opener is used to reduce the draft on the animal.

Top of page

Top of page

e.Tractor Mounted Seed Drill

Special Features |

|

|---|---|

Specification |

Type : Tractor drawn |

Top of page

Top of page

f.Bullock drawn harrower

Special Features |

|

|---|---|

Specification |

Type : Bullock drawn |

General Information:

Small harrows are suitable for use with animal power. They can be moved in the inter-row spaces and used for removing the weeds effectively. The sweeps are blades that move horizontally under the soil and the shallow rooted weeds are easily pulled out. The sweep used with the central line has horizontal wings extending on both the sides and the sweeps used with the side lines have the wing on the right or left away from the crop rows.

Top of page

Top of page

Post Havest Implements

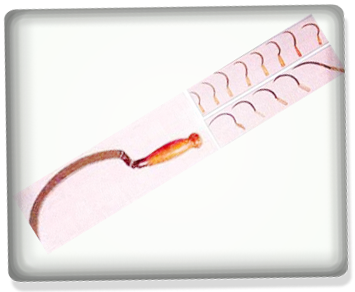

a.Improved Sickles of Different Designs

Special Features |

|

|---|---|

Specification |

Type : Hand operated |

General information:

It consists of curved steel edged blade fixed to the wooden handled the cutting edge may be plain or serrated depending upon the design. The curvature of the blade differs widely in plain edged and serrated sickles. The blade is fabricated from medium carbon or high carbon steel and hardened to resist wear. The blade has a knife section and thickness reduces towards the cutting edge. The tang of the blade is inserted in to the wooden handle for joining the blade to the handle. The wooden handle is either straight or bent at the end.

Top of page

Top of page

b.Multi Crop Thresher (TNAU, Coimbatore)

Special Features |

|

|---|---|

Specification |

Dimension : 3420x2430x2330 |

General information:

The thresher consists of threshing cylinder, oscillating box, straw walker, and winnowing and cleaning attachment. The rasp-bar cylinder is made of cast iron rings, sheet metal and toothed racks and is fitted on the main shaft running on two numbers of heavy pedal bearings. Various pulleys of different sizes are fitted on this shaft to transmit power to winnowing and fan attachment. Adjustments for cylinder and blower speeds and concave clearance are provided to make the machine suitable for various crops.

Top of page

Top of page

c.SBI Grain Thresher

Features |

|

|---|

Top of page

Top of page

d.Grain winnower

Special Features |

|

|---|---|

Specification |

Dimension : 2130 x 600 x 1320 |

General Information

This machine winnows and cleans the paddy and other grains after threshing. It consists of a feed hopper to hold the grain for cleaning. It discharges the grain over a scalper and removes bigger size impurities. A blower provided at the bottom passes air against the grain falling through the scalper which separates the straw, chaff and other impurities. The dust, chaff and straw are collected separately and cleaned paddy is taken out through another outlet near the bottom of the unit.

Top of page

Top of page

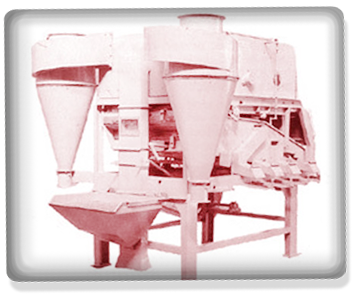

f.Seed Grader- Screen

Special Features |

|

|---|---|

Specification |

Capacity : 1.5-2 tonne/ha |

General Information:

- The seed grader has built-in cyclone dust collectors, various air regulations arrangement, adjustable feeding level and feed control, interchangeable screens and double air aspiration system, pneumatic feedings, dynamically balanced double aspirator fans, air chamber and sieve deck assembly.

- All these units are mounted on a sturdy machine frame. Before falling on top screen, grains are subjected to primary aspiration, which drains off chaff, straw, dust, deceased grains etc.

- Material is then passed through two sieve layers for separation. After passing through screen cleaned/graded material again passes through air sifter and aspiration where remaining light particles are sucked off by a strong upward draught of air. Final product and impurities are collected separately through discharge chutes.

Top of page

Top of page

g.Seed Grader – Screen with Indented Cylinder

Special Features |

|

|---|---|

Specification |

Dimension : 3160 x 1460 x 2560 |

General Information:

- It consists of feed hopper with feed roller and feed control gate, set of sieves, dynamically balanced aspirator fan, step less variable air controls, air chamber, sieve deck assembly, spouts, and indented cylinder grader. All these are mounted on a sturdy steel frame.

- Seeds/Grains are fed into a feed hopper where they are evenly distributed by a feed roller and drop through a controlled gate on the top sieve. Before falling on top screen grains are subjected to primary aspiration, which drains off chaff, straw, dust, deceased grains etc.

- Material is then passed through two sieve layers for separation according to width and thickness. After passing through screens, cleaned/graded material again passes through air sifter and aspiration where remaining light particles are sucked off by a strong upward draught of air.

- After size grading, material passes through indented cylinder grader for removing impurities based on length. Final product and impurities are collected separately through discharge chutes.

Top of page

Top of page

g.Mini Millet Mill

Special Features |

|

|---|---|

Specification |

Capacity : 30-40 Kg per hectare |

Top of page

Top of page

h.Food extruder

Special Features |

|

|---|---|

Specification |

Overall dimension : 960 x 750 x 600 mm |