| TECHNOLOGIES IN CFTRI

ONE STOP SOURCE FOR GLOBAL FOOD TECHNOLOGY

CFTRI is a complete food research laboratory, with a sharp focus on the development and globalisation of processes and products that are commercially attractive, nutritionally superior and safe. For food industries aiming to be the first to hit the market with a new product, we offer total technology solutions- our capabilities, facilities and services-along with an extensive range of technology options. These solutions and options would be of immense value to tiny, small, medium as well as large scale units of the food industry, and invaluable to you too, if your watchwords are-

Long-term strategic research, supported by advanced infrastructure to meet the global technology challenges emerging in the industry.

SOLUTIONS AND OPTIONS IN MULTIPLE DOMAINS

- Basic Food Systems and Processes

- Process Engineering and Plant Design

- Food Biotechnology

- Analytical Quality Testing

- Professional Training

- Technology Options

BASIC FOOD SYSTEMS AND PROCESSES

CFTRI is totally equipped to address basic problems in understanding food system components (chemical, nutritional, toxicological, biomolecular, biophysical, microbiological, physiological and sensorial profiling, and food engineering) to evolve commercially viable processes and consume-friendly products.

BASIC PROCESSES

- Molecular studies

- Molecular distillation

- System design

- Computer aided design

- Flavour targeting

- Engineering properties of food

- Food enzymes

- Rheology of foods

- Natural colours

- Energy minimization process

- Biotechnology

- Process optimization

- Molecular mechanisms of biomolecules

- Environment-friendly processes

- Dietary factors as prophylactics

SPECIALISED SERVICE SUPPORT

- Consultancy assistance for food-based projects

- Contract research (through time-bound R&D projects) for product development and trouble-shooting in food processing and biotechnology areas

- Patent rights management and marketing

- Supply of products (in limited quantities, for quality/market evaluation)

- NICFOS/FOSTIS for high-tech information services

TECHNOLOGIES AVAILABLE

PROTEIN FOODS

-

Infant food: High-protein, optimized 12% protein, lactose-free

-

(milk-based)

-

Mustard/Rapeseed: Integrated processing

-

Protein isolate: Groundnut, soya

-

Dehulling of sesame

-

Processing of sunflower seed

-

Weaning food: Roller dried

-

Bal-Ahar: A weaning food

-

Composite protein food

-

Edible groundnut flour

-

Leaf protein concentrate

-

Malted weaning foods

-

Multipurpose food

-

Edible soya flour

PLANTATION AND SPICE PRODUCTS

-

Preparation of annatto dye

-

Deterpenation of citrus oils

-

Monsooning of cherry coffee

-

Cocoa: Bean curing, cocoa mass, cocoa butter, cocoa powder

-

Compounded asafoetida

-

Cardamom-fixation of green colour

-

Coriander dhal, supari

-

Desiccated coconut

-

Spray-dried coconut milk powder

-

Encapsulated food flavours

-

Food colours (natural): Beetroot, safflower, kokum, grapes

-

Garlic powder

-

Dehydration/drying of ginger

-

Kokum: concentrate and powder

-

Mustard powder

-

Pepper: White, green and dehydrated green pepper

-

Sterilisation of black pepper

-

Plant growth promoter containing n-Triacontanol

-

Drying (including dipsol formulation, fractionation) of red chillies

-

Spice oils: Pepper, ginger, turmeric, cardamom

-

Spice oleoresins: Pepper, ginger, turmeric, chillies

-

Tamarind: Concentrate and powder

-

Turmeric: Curing and polishing

-

Walnut processing

-

Product of phycocyanin from Spirulina

-

Rural-based biotechnological production of Spirulina

FRUIT/VEGETABLE PRODUCTS

-

Fruit bars: Mango, banana, guava, apple

-

Fruited cereal: Mango, apple, banana

-

Fruit juice concentrate/paste: Mango, pineapple, apple, orange, tomato

-

Fruit juice powder: Mango, banana, guava, tomato

-

Fruit and vegetable dehydration: Grapes, banana, onion, potato, peas

-

Instant pickles: Mango, lime

-

Continuous production of jam

-

Papain: Crude, IP, BPC, concentrate

-

Pectin from pectinaceous materials

-

Strained baby foods: Wet or dry (fruit, vegetable, meat, egg)

-

Anti-fungal paste for bananas

-

Canning of curried vegetables

-

Fruit jams, jellies, preserves and candies

-

Fruit toffees

-

Fruits and vegetables: Canning, refrigeration and freezing

-

Mango pulp: Bulk preservation for RTS beverage

-

Tamarind juice concentrate

-

Mango ripening: Accelerated process

-

Dehulling of muskmelon seeds

-

Mushroom culture

-

Preparation of pickles and chutneys

-

Pineapple: Osmo-air-dried

-

Potato products: Flour, flat dry chips, wafers, slices

-

Tomato products: Preparation (including ketchup concentrate from tomato paste)

-

Formulation and use of wax emulsion for extending the shelf-life of fruits and vegetables

-

Oyster mushroom production and dehydration

BEVERAGE PRODUCTS

-

Coffee beverage : Carbonated (including coffee concentrate)

-

Coffee/Tea whitener

-

Flavour blends: Cola, orange and lime/lemon

-

Flavoured tea and instant tea

-

Lactic beverage: Cereal-based

-

Liquid fruits (Clarified fruit juices) from banana, grapes, guava, cashew

-

Malted beverage

-

Toned milk with vegetable protein

-

Carrot juice: Beverage and RTS

-

Ginger cocktail

-

Groundnut milk/curd

-

Honey beverage

-

Comminuted orange beverage base

-

Pan supari nectar

-

Pomegranate juice and products

-

Bottling and preservation of sugarcane juice beverage

-

Fruit syrups and squashes

-

Litchi products: Canned, squash

CONVENIENCE FOODS

-

Ready mixes: Idli, vada, dosa, chakli, jamun, jilebi, maddur vada, pakoda, flavoured flan, soya-based rasagolla, canning of rasagolla

-

RTE convenience food: Khakra

-

Orange peel curry/chutney

-

Cereal flakes: Rice, jowar

-

Instant traditional foods: Bisibele bhath, puliogare, sambar, rasam, pongal, urd bhath, imli-poha

-

Fast foods

CEREAL AND PULSE PRODUCTS

MICROBIAL AND FERMENTATION PRODUCTS

-

Alcohol from banana, cashew apple, mahua flowers, grapes, tapioca

-

Baker's yeast

-

Yeast strain from alcohol production

-

Food enzymes: Fungal amylase, amyloglucosidase, pectinase

-

Aflatoxin decontamination

-

Natural vinegar: Generation (including generator design) from jaggery, toddy, pineapple

BAKERY PRODUCTS

-

Biscuit formulations: Cocoa, cocoa cream, nutro, high protein

-

Baking powder

-

Biscuit formulations: Salt and sweet

-

Production of bread: brown, plain, sweet, milk, whole wheat, fruit

-

Premix-based foods: Bread, biscuit, cookies

-

Composite ragi bread

-

Composite bajra bread

-

Instant cake mix

-

Sugar-free biscuits

-

Onion biscuits

-

Speciality bakery models

MEAT, FISH AND POULTRY PRODUCTS

-

Chicken: Dressing line and products

-

Chitosan

-

Corned beef

-

Egg albumen flakes, egg powder, egg washing and egg coating for extension of shelf life

-

Fish: Meal and oil, thermal processing of fish products, pickles, freezing of fish products

-

Instant gravy mixes (dehydrated)

-

Meat gravy concentrate

-

Shark fin rays

-

Shrimp: Canning, freeze drying

-

Animal feed formulation: Cattle and poultry

-

Bacon and ham: Preparation

-

Bactopeptone from fish waste

-

Chicken products: Sticks, curries, tandoori, kabob

-

Mackerel: Salt curing, drying

-

Meat: Soup cube, gravy concentrate, tenderisation

-

Conditioning of mutton

-

Mutton pickle

-

Sausage casings: Natural

-

Sausage: Meat, fish, chicken, pork and natural sausage preparation

-

Traditional HAE/RTC meat/poultry: Frozen chicken tandoori, kabob, breaded chicken kabob and chicken sandwich spread (HAE), frozen mutton shami kabob (HAE/RTC), curry (HAE) (chicken, pork, mutton), biryani (mutton, chicken), frozen biryani (HAE)

-

Dehydrated meat

-

Chicken wafers

FOOD MACHINERY

-

Citrus juice extractor

-

Double effect evaporator

-

Single effect evaporator: 1000/500 kg evaporation per hour

-

Hot air drier: Cabinet/tunnel type for arecanut/cardamom/cashew kernel

-

Herbal extractives plant

-

Maize mill system

-

Mini grain mill

-

Mini rice mill

-

Mini wheat mill

-

Modern dhal mill system

-

Versatile dhal mill

-

Paddy parboiling plant

-

Quick test kit for measuring FFA in rice bran

-

Rice bran stabilising system

-

Roller flaker

-

Continuos chapati making plant

-

Automatic dosa making machine

-

Continuous idli maker

-

Simple rice milling system

-

Double pass single huller

-

Single pass double huller

-

Centrifugal sheller huller

-

Continuous heat sealer

-

Leaf cup machine

-

Paddy crack detector

-

Papad press (hand and pedal operated)

-

Pest proofing machine

-

Simple pulse dehusking machine (hand-operated and mechanised)

-

Strip lacquering machine for tins

-

Triple roller extractor

-

Vegetable slicer

-

Vinegar generator

-

Volumetric filler

-

Jacketed press for solid/liquid separation

OTHERS

-

Zinc EDTA chelate complex

-

Technology protocol for shipping Alphanso/Banganapalli mango

-

Versatile food thickener

-

Custom-made food processing enzymes

-

Textured protein

MAJOR TECHNOLOGIES TRANSFERRED TO INDUSTRY

-

Infant food from buffalo milk: A major import-substitute product

-

Optimized infant food formulation

-

Protein isolate from oilseed meals

-

Shelf-stable egg powder and egg white from fresh eggs

-

Spice oils and extractives

-

Cola beverage concentrate

-

Ready-to-eat (instant) mixes for traditional Indian snacks

-

Natural colours from kokum, safflower petals, beetroot and blue grapes

-

Eco-friendly and cost-effective steam sterilization of black pepper

-

High quality raisins from Indian grapes

-

Curcumin concentrate from turmeric oleoresin

-

Chitosan from shrimp industry waste

-

Aflatoxin-free groundnut oil

-

n-Triacontanol: Plant growth promoter

-

Tomato concentrate production system

-

Integrated utilisation of lime fruit for recovery of oil, citrate and pectin

-

Animal feed formulation from agricultural wastes

-

Alcohol from tapioca

-

Energy Food formulation for national nutrition intervention programmes

-

Protocol for food grain protection, including non-toxic grain protectants

-

Dehulled sunflower seeds

-

Free-flowing compounded asafoetida powder

-

High-fibre biscuit formulation: A health product

-

Protocol for prevention of drip loss in frozen prawns: An export product

TECHNOLOGY DETAILS

COCONUT MILK POWDER

Uses

Spray Dried Coconut Milk Powder can be used as an ingredient for many fish, shellfish, meat, poultry, vegetable dishes, confectioneries, sweets, sherbaths, beverages and other type of preparations.

Introduction

Coconut milk is a product of the region of tropical climate and is in great demand in the culinary. CFTRI has developed a process for production of dehydrated coconut milk powder which retains the natural flavour and texture of coconut milk. It has good keeping quality & greater convenience.

Process

The process for the production of whole coconut milk powder consists of four major steps namely, extraction of coconut milk, formulation of the milk, homogenisation and spray drying. White endosperm of coconut after removal of shell and paring was passed through rotary wedge cutter. The coconut grating is expressed in a screw press to extract coconut milk. Then coconut milk is formulated by addition of necessary ingredients. This formulated coconut milk is pasteurized and homogenised and spray dried.

TRADITIONAL FOODS

Introduction

The flavour of tradition is irrestible and so are the traditional foods. The intricacies of the recipe, the lack of opportunity to practice and master the art have tended to forego these delights to the gourmets and commons. Through modern food science and technology these traditions are now available with the added convenience.

Use

Ready mixes of snacks and sweets - such as Dosai, Idli, Vada, Gulab Jamun, Jilebi, Chakli, Maddur Vada, Pakoda. Instant traditions suchs as Puliogare, Sambar, Rasam, Pongal, Urd Bhath, Gojjavalakki.

Process

The raw materials are cleaned and roasted. The roasted materials are coarse grounded, sifted and mixed with other ingredients. The process will differ according to the type of final product. Cleaning, drying, ginding, size grading, cooking, dehydration, disinfestation, mixing, packing are the major unit operations involved in the preparation of traditional Indian foods.

GRAVY MIXES

Introduction

The instant mixes are dehydrated products of complete ingredients (recipe) of the curry except the solid pieces of meat/fish or vegetables. The dehydrated instant gravy mix is reconstituted with water at the point of use as used as gravy or marinating mix as the case may be in the preparation of respective dish.

Process

CFTRI has developed process for production of dehydrated instant mixes for gravies (curry) of six types.

- Gravies for meat preparations

- Madras Kurma

- Mutton Chilly fry

- Gravy for fish preparations

- South Indian fish gravy

- Rohu masala

- Fish fry masala

- Goan fish curry

- Multi - purpose gravy

- Meat

- Chicken

- Vegetable

- Egg

- Biriyani mix (mutton, chicken,vegetable)

- Tandoori chicken marinating mix

- Kabab mix (Ginger chicken kabab and lasone kabab)

INSTANT CAKE MIX

Introduction

Instant cake mix is premix containing all the ingredients normally used for the preparation of cake. Cakes could be easily prepared from such premix by adding a required quantity of water to the premix and mixing for a specified period of time and baking the batter in a baking oven. It adds variety to snack foods in the house hold. The advantage of the use of such mix is convenience as it eliminates the drudgery of purchasing ingredients in small quantities, weighing them and creaming them separately for a longer duration during the preparation of batter which is a very cumber some procedure.

Market Potential

In the developed countries, cake premix are extensively used at home as well as in bakeries as they offer technological convenience and varieties. In India, very little work has been done for the developed and popularization of such premixes, since bakery premixes are relatively new products, a market potential has to be created to be used as a house hold snack food item production of varieties of cake. Cake premix will also be useful for small bakery chains to prepare consistent quality products by preparing the mix at centralized place.

Process

-Dry ingredients

-Sieving

-Blending

-Fumigation

-Filling

-Sealing

-Storage

SUGAR-FREE BISCUITS

Introduction

Ordinary "gluco" type biscuits contain about 450 calories and contain sugar up to 25%. The Sugar-free biscuits do not contain any added sugar. Replacement of sucrose became an area of importance in the late 1970s as a number of food industry professionals implicated sucrose in tooth decay, development of obesity, coronary heart disease, high blood pressure, the development of diabetes etc. CFTRI developed and standardised a formulation for sugar free biscuit which can be used by diabetes.

Process

Sugar-free biscuits are made from soft dough based on the creaming method and processed in rotary moulder. The biscuits are baked in a continuous tunnel type oven as followed for sweet 'gluco" type biscuits.

CFTRI has developed a special formula containing safe sweetness, which can give crisp texture and sweet taste to the final product.

Nutritional Fact

Protein : 6% Fat: 10% Carbohydrate: 45%

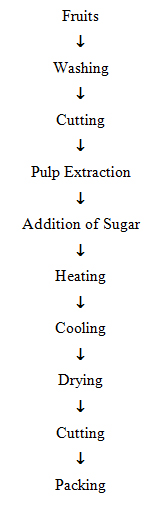

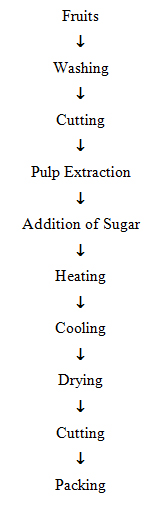

FRUIT BARS (MANGO, APPLE, GUAVA, BANANA)

Introduction

Fruits can be preserved either in the fresh state or processed form. Fruit bar is a concentrated product with good nutritive value. It is very appealing and consumed readily as a confectionery product. It can be packed and sold in attractive pouches. The product is hygienic and has a good shelf life.

Market potential

Fruit bars are confectionery products and can find a good market in the urban as well as rural area for its taste, aroma and convenience in use. A dynamic marketing net work can boost of this product in India and abroad.

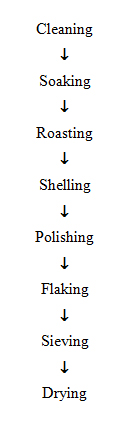

CEREAL FLAKES -RICE

Introduction

Rice flakes are known by several names such as flaked Rice, Beaten rice, Aval, Avalakki, Poha and Chiwda. Rice flake is one of the many traditional products in India. With this background, the CFTRI developed a process for improved Rice flaking. The improved process has the advantage of increase in yield and better quality products, besides economic utilization of by-products. It is suitable for preparing soft-cooked (bath), toasted and seasoned mixture, energy weaning food, Tamarind bath, upma, sweet pongal, sweet gravy.

Market Potential

The market for flaked rice will predominantly consist at buyers from group especially of urban and semi-urban areas. Even the people of low-income group can also buy as the products are directly consumed along with jaggery and from coconut pieces by rural folk.

Process

The process for manufacturing the rice flakes involves following steps:

FOR FURTHER DETAILS VISIT www.cftri.com

TECHNOLOGIES IN IICPT

PRESERVATION AND STORAGE

1) High moisture paddy

2) Parboiled paddy during rainy season

3) Wet paddy straw

4) IPM of psocids

DRYING

1) MYDI

2) PPRC Dryer

PARBOILING

1) Prevention of off odour

2) Prevention of husk opening

3) Steamed rice

4) SST method of parboiling

5) Pressure parboiling

6) Sand parboiling

7) Thermic fluid parboiling

8) Parboiling of brown rice

MILLING

1) Modernization of huller mill

2) Low friction huller

PRODUCTS AND EQUIPMENT

1) Idli dry mix

2) Crispy mix

3) Continuous rice puffing equipment

4) Fortification of puffed rice

5) Rice vermicelli

6) Quick cooking sooji

7) Quick cooking rice

BYPRODUCTS AND EQUIPMENT

1) Rick husk ash as carrier for bio-fertilizers

2) Husk stove

3) Bran stabilizer

4) Degermer

POLLUTION CONTROL

Effluent treatment plant for rice mills

CONTACT US

Indian Institute of Crop Processing Technology

(Ministry of Food Processing Industries, Govt. of India)

Pudukkottai Road,

Thanjavur 613 005

|