| Post Harvest Technology :: Vegetables |

|

|

|

|

|

Value added products in Moringa

Value Addtion In Moringa

Moringa oleifera belonging to the monogeneric family, Moringaceae is well known for its nutritive value in leaves, pods, and seeds. It contains high protein content in the leaves, twigs, stems and seeds. They are an exceptionally good source of provitamin A, vitamins B and C, minerals (particularly Iron) and sulphur containing amino acids methionine and cysteine. It is commonly said that moringa leaves contain more Vitamin A than carrots, more calcium than milk, more iron than spinach, more Vitamin C than oranges, and more potassium than bananas,” and that the protein quality of Moringa leaves rivals that of milk and eggs. However, the leaves and stem of M. oleifera are known to have large amounts of their calcium bound in calcium oxalate crystals. For maximum utilization of available nutrients in moringa, value added products are prepared from different parts, which are as follows.

1. Leaf preparations

a) Moringa leaf powder

The leaves after harvest should be stripped off the stems, washed and dried in shade (sunlight can destroy vitamin A). The dried leaves are made into fine powder which can be stored in a air-tight containers. Vitamin A retention is enhanced if the leaves are blanched before drying. (Subadra et al., 1997). As a nutritional additive, 2 or 3 spoonful of the powder can be added to soups or sauces. Moringa leaf powder can be stored for up to 6 months when protected from light and humidity.

b) Moringa juice

Fresh leaves are crushed and pounded in a mortar with a small amount of water. For larger production, hammer mill is used to pound young moringa shoots (not more than 40 days old) together with little water (about one liter per 10 kg fresh material).Then it is filtered and diluted with water and sugar is added for taste. Alternatively, spoonful of more moringa leaf powder can be added to a litre of water. Then it is stirred together, strained and sugar is added. Juice or juice concentrate is stored in a refrigerator.

c) Moringa leaf sauce

Two cups of fresh leaves are steamed for a few minutes in one cup of water. Chopped onions, salt, butter and any other seasonings are according to taste (Meitzner and Price, 1996).

2. Preparations from flowers

The flowers are a good source of calcium and potassium and should be cooked and consumed. Fried alone or with a batter they have a taste reminiscent of mushrooms. Moringa flowers can be mixed with any leaf recipes or steamed and eaten as a salad.

3. Preparations from pods

The entire young and pliable pod is cooked and eaten or used in the preparation of curries. In older pods which develop tough exterior, the pulp and immature seeds remain edible just before ripening begins. A dish is made by slicing pods into 5 cm lengths and boiled in water along with lentils. The flesh inside the pod sections is eaten.

Alternatively, pods can be opened and the flesh and young immature seeds scraped out pods are boiled in water for a few minutes. The seeds of edible pods should be white in color. The seeds should be scraped out with the winged shells intact and as much of the soft white flesh as possible. It is rinsed with water to remove the sticky, bitter film. It is mixed with rice or roasted or fried in oil to give a taste like sweet groundnuts. The flesh can be cut into strips and steamed or fried, used to make a soup or be added to other sauces.

Salads are also prepared from moringa pods. Very young moringa pods (should be less than 1 cm thick and snap easily) are selected and they are cut into 3 cm lengths. It should be steamed for 10 minutes and then marinaded in a mixture of oil, vinegar, salt, pepper, garlic and parsley.

A recipe called moringa beans is prepared using very young moringa pods (should be less than 1 cm thick and snap easily). The pods are sliced into pieces of any length and steamed or boiled until tender.

4. Preparations from seeds

The seeds can be boiled for few minutes to remove the fine transparent hull and the water should be drained. Seeds should be eaten green before they change colour to yellow. The dry seeds can be ground to a powder and used for seasoning sauces.

5. Root preparations

The moringa tree has been called the “horseradish tree” because a similar-tasting condiment can be made with from its pungent roots. Even when the plant is only 60 cm tall, it can be pulled up and the roots harvested. The roots from young plants can also be dried and ground for use as a hot seasoning base with a flavour similar to horse radish. A tasty hot sauce from the roots can also be prepared by cooking them in vinegar. The root bark (which contains two alkaloids as well as the toxic moringinine) must be scraped off. The interior flesh is pounded, then mixed with salt and vinegar.

However, it can be dangerous to consume the roots too often or in large amounts. Even when toxic root bark is removed, the flesh has been found to contain the alkaloid spirochin, a nerve paralyzant (Morton, 1991).

6. Moringa oil

Moringa oil or Ben oil is obtained by pressing the seeds. The oil content of de-hulled seed (kernel) is approximately 42 %, which is brilliant yellow coloured. It is used as a lubricant for fine machinery such as timepieces because it has little tendency to deteriorate and become rancid and sticky (Ferrao and Ferrao, 1970; Ramachandran et al., 1980). It is also useful as a vegetable cooking oil. The free fatty acid content varies from 0.5 to 3 %. Indian Ayurveda claims that moringa oil also possess antitumor, antipyretic, antiepileptic, anti-inflammatory, antiulcer, antispasmodic, diuretic, antihypertensive, cholesterol lowering, antioxidant, antibacterial and antifungal activities, and are being employed for the treatment of different ailments in the indigenous system of medicine, particularly in South Asia.

a) Cosmetic products

Moringa oil has tremendous cosmetic value and is used in body and hair care. Moringa oil has been used in skin preparations and ointments. It has nourishing and emollient properties, making it an excellent massage oil due to the presence of palmitoleic, oleic and linoleic acids, vitamins A and C and unsaturated fatty acid.

This moringa oil is in demand because it is so stable and resistant to rancidity and it has long been valued for its enfleurage property by the perfume industry. It is useful in the manufacture of perfume and hairdressings. The oil is known for its capacity to absorb and retain volatile substances and is therefore valuable in the perfume industry for stabilizing scents and the oil has been used in skin preparations and ointments since Egyptian times.

|

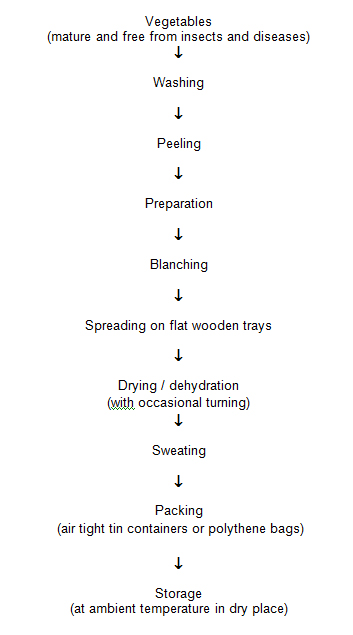

| FLOWCHART FOR DRYING / DEHYDRATION OF VEGETABLES** |

|

|

|

|

Moringa Pickle:

Click here for Demo Video |

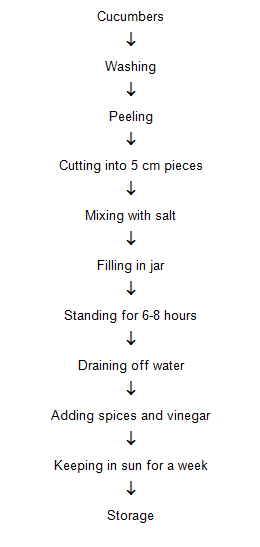

| CUCUMBER PICKLE *

Cucumber 1 kg, salt 200 g, red chilli powder 15 g, cardamom (large), cumin, black pepper (powdered) each 10 g, clove (headless) 6 numbers, vinegar 750 ml. |

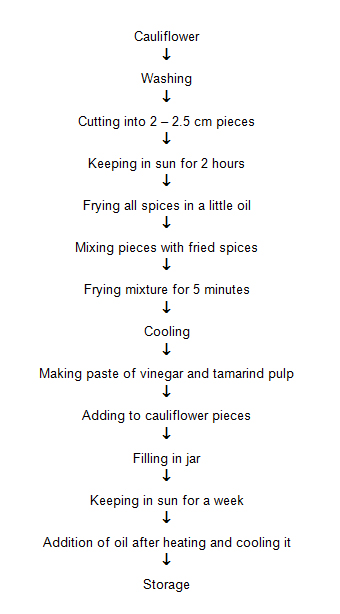

CAULIFLOWER PICKLE *

Cauliflower (pieces) 1 kg, salt 150 g, ginger (chopped), 25 g, onion (chopped), 50 g, garlic (chopped) 10 g, red chilli, turmeric, cinnamon, black pepper, cardamom (large), cumin, aniseed (powdered) each 15 g, clove (headless) 6 numbers, tamarind pulp 50 g, mustard (ground) 50 g, vinegar 150 ml, mustard oil 400 ml. |

| PROCESSING FLOW-SHEET FOR CUCUMBER PICKLE |

|

|

| Processing flow-sheet for cauliflower pickle |

|

|

|

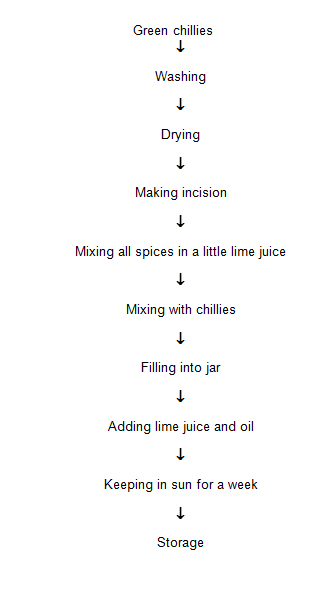

GREEN CHILLI PICKLE*

| Green chillies |

- |

1 kg |

| Salt |

- |

150 gm |

| Mustard (ground) |

- |

100 gm |

| Lime juice |

- |

200 ml |

| or |

| Amchur |

- |

200 gm |

| Fenugreek cardamom |

- |

(large) |

| Turmeric, cumin (powdered) each |

- |

15 gm |

| Mustard oil |

- |

400 ml |

|

| PROCESSING FLOW-SHEET FOR GREEN CHILLI PICKLE |

|

|

|

| GARLIC PICKLE *

-

Peel, steam the garlic for 5 minutes and grind into a paste.

-

Heat little amount of oil and season mustard.

-

Fry the ground garlic for a few minutes.

-

Add lime juice, along with remaining oil and bring to it boil.

-

Finally add jaggery and all other spices and complete cooking.

-

Bottle the product, while hot.

|

VEGETABLE SOUP MIX**

Ingredients: Onions, carrot, beans, cauliflower, cabbage, tomato and spinach.

Preparation of vegetable powders

All the selected vegetables were washed well in running tap water. Then it was cut into small pieces and steam blanched for 3.0 – 5.0 minutes except onion and tomatoes. All the vegetables except onion (60  and 7 hrs) were dried in the cabinet drier at 80 and 7 hrs) were dried in the cabinet drier at 80  for 10 hrs separately. The dehydrated pieces were then ground into powder in a mixie. for 10 hrs separately. The dehydrated pieces were then ground into powder in a mixie.

Preparation of mixed vegetable soup mix

Vegetable powders – 50 gm (carrot: beans : cauliflower : cabbage: tomato : spinach 1:1:1:1:1:1)

Onion powder |

5 g |

| Corn flour |

20 g |

| Cumin |

5 g |

| Pepper |

3 g |

| Salt |

15 g |

| Agenomotto |

5 g |

|

Method

All the ingredients were mixed thoroughly and packed in polythene bags. Ten gram of the prepared mixed vegetable soup mix was added to 150 ml of boiled water and stirred thoroughly. |

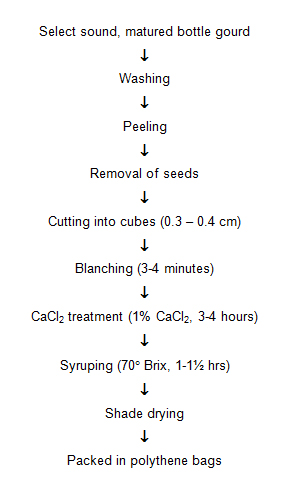

PREPARATION OF TUTTI-FRUITY FROM BOTTLEGOURD (ONE DAY PROCESS METHOD)**

FLOW CHART FOR CURING OF FRESH BOTTLE GOURD**

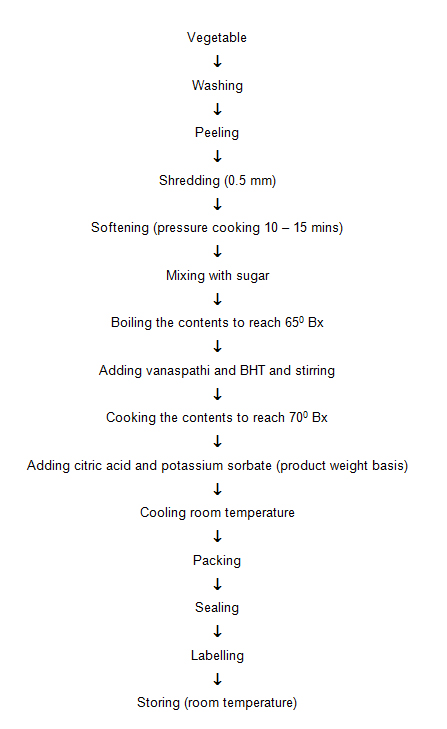

PREPARATION OF VEGETABLE HALWAS*

PROCESSING OF READY-TO-USE CLUSTER BEAN PORIYAL**

CORN SOUP MIX**

Ingredients: Baby corn, onions and tomato.

All the vegetables were washed well in running tap water. Then it was cut into small pieces and steam blanched for 3.0 – 5.0 min. except onion and tomatoes. Then it was dried in the cabinet drier at 80  for 10 hours except onion (60 for 10 hours except onion (60  and 7 hrs). The dehydrated pieces were then ground into powder in a mixie. and 7 hrs). The dehydrated pieces were then ground into powder in a mixie.

Preparation of corn soup mix

Ingredients

|

|

| Baby corn powder |

25 g |

| Tomato powder |

25 g |

| Onion powder |

5 g |

| Corn flour |

20 g |

| Cumin powder |

5.0 g |

| Pepper powder |

3.0 g |

| Salt |

1.5 g |

| Agenomotto |

0.5 g |

|

Technologies Available |

* - Post Harvest Technology Centre, TNAU, Coimbatore.

** - Home Science College and Research Institute, TNAU, Madurai.

|

|

|

| . |

Updated on May,2014 |

|

|

Home | About Us | Success Stories | Farmers Association | Publications | Contact Us

© 2015 TNAU. All Rights Reserved. |

|

|

|