|

|||||||||||||||||||||||||||||||||||||

| Home | About Us | Success Stories | Farmers Association | Farmers' Innovation | Publications | Contact | |||||||||||||||||||||||||||||||||||||

| Cereals :: Rice | |||||||||||||||||||||||||||||||||||||

VALUE ADDITION

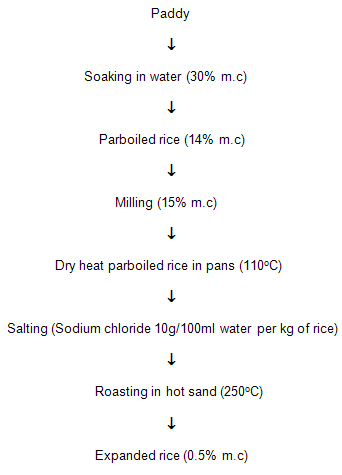

Parched rice * It is prepared by throwing rice in sand heated to a high temperature in an iron or mud pan. On stirring, rice begins to crackle and swell. Then the content of the pan are removed and sieved to separate the parched rice from sand. Parboiled rice is used for making grayish to brilliant white colour parched rice and sold either salted or unsalted. It is eaten as such or mixed with butter milk or milk. Expanded cereals Expanded rice (Pori) * Expanded rice (murmura, pori, muri) is a traditional convenience food widely consumed in India either as such or with Jaggery, roasted Bengal gram and shredded vegetables and spices. The product is mostly produced in home or cottage sector by skilled artisans. In the traditional process, the paddy is soaked in water preferably over night until saturation, drained and then either steamed or dry roasted in sand for parboiling. The parboiled paddy is milled, salted and again roasted in sand for expansion. Flow chart

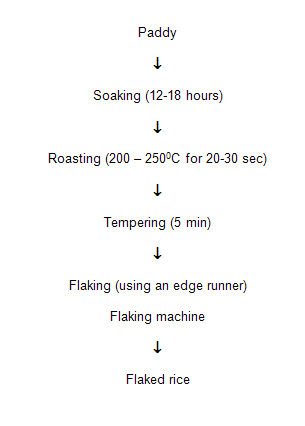

Puffing / Popping * Puffed rice :- (using rice) This popular ready-to-eat snack product is obtained by puffing milled parboiled rice. In the traditional process rice is gently heated on the furnace without sand to reduce the moisture content slightly. It is then mixed with salt solution and again roasted on furnace in small batches with sand on a strong fire for a few seconds to produce the expanded rice. Rice expands about 8 times retaining the grain shape and is highly porous and crisp. Parched paddy or puffed rice:- (using paddy) Sun dried paddy is filled in mud jars and is moistened with hot water. After 2-3 min. the water is decanted and the jars are kept in an inverted position for 8-10 hours. Next the paddy is exposed to the sun for a short time and then parched in hot sand as in the preparation of parched rice. Puffed rice is prepared by throwing pretreated paddy into sand heated to a high temperature in an iron pan. During parching the grain swell and burst into a soft white product. The parched grains are sieved to remove sand and winnowed to separate the husk. Puffed rice from parboiled rice The rice is soaked in salt water to increase the moisture to about 20%. The moist rice is introduced into a hot vessel at about 250-275 Popped rice This is yet another traditional value added product prepared from raw paddy. The paddy at a moisture content of 12-14% is directly roasted in iron pans using sand as a medium at a temperature of 150-200 Flaking * Flaked rice is another important value added product prepared from paddy. Traditionally, it is prepared from soaked paddy, after heat treatment and immediate flattening using a flaking machine (an edge runner).

Flaked rice is made from parboiled rice. Paddy is soaked in water for 2 -3 days to soften the kernel followed by boiling water for a few minutes and the water is drained off. The paddy is heated in a shallow earthen vessel or sand in iron pan till the husks break open. It is pounded by a wooden pestle which flattens the kernel and removes the husk. The husk is separated by winnowing. Flaked rice is thin and papery and of white colour. Quick cooking rice is made by steeping polished rice in water to a moisture content of 35 per cent, cooking under pressure and drying. Alternatively the rice may be subjected to freezing, thawing and dehydration. Derived products Polished rice may be precooked and canned as rice pudding and also used to make dry breakfast cereals. 2. FERMENTED PRODUCTS BASED ON RICE Idli * Idli is a small, white acid – leavened, and steamed cake made by bacterial fermentation (12-18 hours) of a thick batter made from rice and dehulled blackgram dhal. Idlies are soft, moist and spongy had a desirable sour flavour. For idli, the rice was coarsely ground and the black gram was finely ground.

The soft spongy texture observed in the leavened steamed idli made out of black gram is due to the presence of two components, namely surface active protein (globulin) and an arabinogalactan (polysaccharide) in black gram. The mucilaginous principle of blackgram is identified as arabinogalactan. It is believed that this mucilaginous principle helps in the retention of carbondioxide during the fermentation of the thick batter and is thus responsible for the soft spongy honey comb texture of the idli. Fermentation brings about physical and chemical changes in the idli batter. With the progress of fermentation there is an increase in batter volume, acidity and non protein nitrogen.

Dosa * Dosa is another common fermented product used in India. This is prepared from a fermented batter of rice and pulse in the proportions ranging from 6:1 to 10:1. Both the ingredients are finely ground, unlike in the idli batter which contains the rice component in a coarse consistency. The dosa batter is very thin and dosa is baked on a hot pan. The thickness of a thin pancake depends upon the consistency of the batter. Thin batter gives a thin pancake, although it may stick to the pan.

Dhokla Dhokla is a fermented food prepared from rice and bengal gram. This is popular in West India, particularly Gujarat. This is prepared from a batter of coarsely ground rice and bengal gram. The fermented batter is steamed in a pie dish, cut into diamond shape and seasoned.

Other fermented products Some other fermented foods based on rice used in the country are ambali, prepared from a thick fermented batter of finger millet flour and rice, ganji, fermented, surplus water from cooked rice and fermented rice or kali which is left over cooked rice to which water is added and the mixture allowed to ferment overnight. 3. PREPARATION OF EXTRUDED PRODUCTS Extrusion is a process that combines several unit operation including mixing. kneading, shearing, heating, cooling shaping and forming. It involves compressing, and working raw material eg. Flours, starches, proteins, salt, sugar and other minor ingredients to form a semi solid mass under a variety of controlled conditions and then forcing it to pass through a restricted opening such as a shaped hole or slot at a predetermined rate. Heat in applied directly by steam injection or indirectly through a heated barrel. The final process temperature in the cooking extruder can be high as 200°C but the time of exposure to heat is relatively short (10-60 seconds). The extrusion cooking is also called a high temperature short time (HTST) process. Extruded products Rice based extruded products include sevai, idiappam, murukku (chakli) rice based vadagam etc. Rice based noodles and noodles from fermented rice flour are popular in China, Japan and the orient.

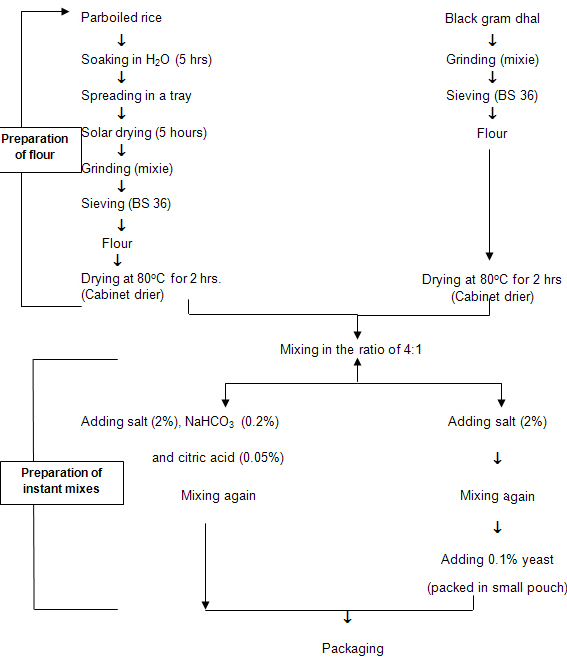

a. PREPARATION OF IDLI MIX * Instant idli mixes eliminate the traditional method of grinding of both the ingredients and the leavening is produced by the action of chemical leavening agents. Preparation of rice and black gram flours The parboiled rice IR 20 was soaked in water for 5 hours. Then the water was drained completely and dried in solar drier for 5 hrs. The dried rice was ground in a mixie and sieved through BS 36 sieve. Black gram dhal was also ground in a mixie and sieved (BS 36). The rice and black gram flour were dried in a cabinet drier at 80 The parboiled rice IR 20 was soaked in water for 5 hours. Then the water was drained completely and dried in solar drier for 5 hrs. The dried rice was ground in a mixie and sieved through BS 36 sieve. Black gram dhal was also ground in a mixie and sieved (BS 36). The rice and black gram flour were dried in a cabinet drier at 80

Materials required

Method

b. PREPARATION OF INSTANT IDIAPPAM MIX * Idiappam is a traditional food prepared from the combination of parboiled rice and raw rice. It is consumed as breakfast / dinner for the peoples especially South Indians. It is a steamed product and consumed as either in the form of sweet or savoury dish (lime bath, tomato bath and curd bath).

Procedure Preparation of rice flour The parboiled rice – IR 20 and raw rice was soaked in water for 5 hours separately. Then the water was drained completely and dried in the solar drier for 5 hrs. The dried rice was ground in a mixie and sieved through BS 36 sieve. Materials required

Method Mix all the ingredients and stored, in the polythene bag. Preparation of idiappam The idiappam mix (100 g) was steamed in a steaming unit for 5 minutes (idli cooker). To the steamed flour, required quantity of boiling water (90 c. Preparation of murukku instant mix * Method Raw rice and black gram were ground in a mill separately and sieved through 80 BS sieve and used for the preparation of murukku instant mix.

Ingredients

The crispy mix was prepared by mixing raw rice flour, black gram dhal flour, salt and sesame seed. The mix was passed through 80 BS sieve for uniform mixing. Method for the preparation of murukku The dough was prepared by the addition of hydrogenated fat –5 g and water and extruded in a hand extruder of local make with 4 mm diameter orifice and fried in the heated oil at 180 d. PREPARATION OF VADAGAM *Vadagam is a traditional product mostly prepared from rice flour and also sago. It is a deep fat fried product and consumed as a side dish in the meals

Preparation of vadagam Materials required Raw rice flour, green chillies, cumin seeds and salt.

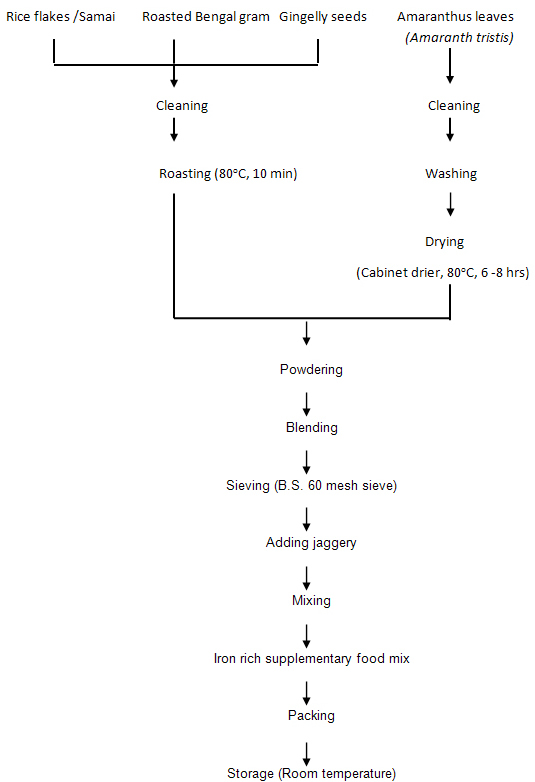

Method The ingredients were mixed and 250 ml of water was added and cooked for 10 minutes until a thick extrudable paste was formed. The hot paste was extruded in hand extruder (dia 5 mm) and dried in sun for about five hours. The dried vadagam sample was packed in a polyethylene bags and sealed. Frying of vadagam Dried rice vadagam was fried in the refined oil at 180 5. PREPARATION OF SUPPLEMENTARY FOOD MIX **

Technologies Available * - Post Harvest Technology Centre, TNAU, Coimbatore. ** - Home Science College and Research Institute, TNAU, Madurai. Source

|

|||||||||||||||||||||||||||||||||||||

| Home | About Us | Success Stories | Farmers Association | Publications| Contact Us

© 2015 TNAU. All Rights Reserved. |

|||||||||||||||||||||||||||||||||||||