|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Crop Production |

Cereals :: Wheat |

Weather |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

VALUE ADDITION a. Malted Wheat: The process of malting consists following steps

The characteristic malt flavour is developed. The malt is dried to moisture content of about 13%. b. Amylase Rich Food (ARF) is germinated cereal flour, which is extremely rich in the enzyme alpha-amylase. The alpha-amylase cleaves the long carbohydrate chains in the cereal flour into shorter dextrins. Just half a flat teaspoon of any ARF can reduce even a very high total solid concentration of 45g, made up of 25g flour, 15g sweetener and 5g oil cooked in 100ml of water to a soupy consistency. This remarkable property makes it possible to offer the weaning child a low viscosity yet high energy dense preparation. Malted cereal flour is inexpensive and can be used in brewing and in the preparation of malt extract for pharmaceutical purposes and in the preparation of malted milk powder. c. Puffed wheat Whole grain wheat are cleaned and conditioned. It is then fed into an externally heated, sealed pressure chamber. Steam is injected to raise the internal pressure in the chamber to about 14 kg/cm2 and then suddenly released by opening the chamber when owing to the expansion of water vapour the grain is blown up to several times its original size. d. Popcorn has been a traditional snack food. Expansion volume is the most critical quality factor for pop corn. The texture (tenderness and crispness) is positively correlated with popping volume. Most commercial popcorn has a 30-40 fold expansion popping occurs at about 177 e. Wheat flakes : Cleaned grains are tempered in bins and subsequently steamed at atmospheric pressure until they attain moisture of 21%. The steamed wheat is passed through steam rollers which ruptures the bran coat and flatten the whole grain thus making the kernels more permeable to moisture during the cooking step. The flattened kernels are then cooked in rotating retorts along with malt, salt, sugar etc. for 90 min at 20 psi steam pressure. After cooking the grains become soft, translucent and brown and contain moisture around 45-50% with completely gelatinized starch. The cooked grains are heated to 80-85 a. BREAD*

PROCESSING OF WHOLE WHEAT BREAD *

PREPARATION OF HIGH FIBRE BREAD **

b. BUN *

c. CAKES *

d. RUSK/SOUP STICK ** Ingredients

PROCESSING OF RUSK AND SOUP STICKS

PREPARATION OF HIGH FIBRE RUSK **

e. COOKIES *

PREPARATION OF NUTRIENT DENSE LOW-COST INFANT WEANING BISCUITS **

f. DOUGHNUTS * Doughnuts are served quite extensively in hotels, restaurants and snack bars in many countries of the world. When made attractive and tasty, doughnuts can be served at most festive occasions. Doughnuts can become very popular in India for serving at tea time. The ingredients that go to make doughnuts are :

Method 1. Sieve together correctly scaled flour, salt, nutmeg powder, cinnamon powder, milk powder and baking powder thoroughly. g. PUFF PASTRY * Puff Pastry is a rolled pastry in which layers of shortening are interleaved between layers of dough so that upon baking an open network of crisp and flaky layers are formed. The main ingredients used in puff pastry making are flour, shortening, salt and water.

Fillings

h. PIZZA * Ingredients

Fillings

Method

PREPARATION OF KHAKRA *

Ingredients

Method

Khakra were toasted on tawa. The khakra was pressed and turned frequently with a cloth bundle (a thick cloth was folded into a 10 cm square of thickness 5-6 cm. The folded material was placed in another piece of cloth and made into a bundle, so that it was handy to use. This cloth bundle was used to press the khakra while toasting. The pressing process ensured even distribution of heat all over the khakra). The khakra was cook in five minutes. The temperature was 160 PREPARATION OF HIGH FIBRE KHAKRA **

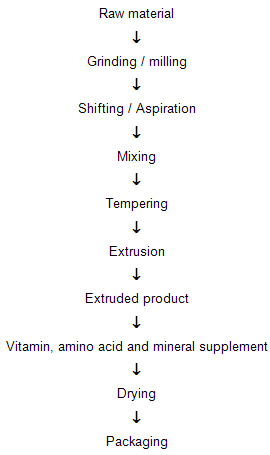

3. PREPARATION OF EXTRUDED PRODUCTSExtrusion is the process of cooking moistened starch food material by combination of heat, pressure and mechanical shear. The minor ingredients which may be added are edible groundnut flour, tapioca flour, soya flour, milk powder, casein, gluten vegetables and spices. Besides they may also be enriched with vitamins and minerals. The manufacturing process for macaroni, spaghetti and vermicelli Extruded products are made from suji or maida, with or without other ingredients, with cold or lukewarm water, kneading it and then extruding it through and extrusion press fitted with a die of the desired shape. The extruded product cut to a given length is then dried to definite moisture content under controlled conditions of temperature and humidity. The dried product is suitably packed depending on the market requirements. Flow Chart  a. Plain Noodles *

Preparation

Pulses, Fruits, Vegetables and Mushroom Incorporated Noodles

Replace maida with 20 per cent pulse flour or millet flours or fruit pulp or vegetable puree to enrich the nutritive value. for example.

Noodle Masala Mix

a. PREPARATION OF NOODLES **

PREPARATION OF HIGH FIBRE NOODLES **

b. Macaroni products Macaroni products also termed as pasta product, include macaroni, spaghetti, vermicelli and noodles. Macaroni is a formed hollow tubes, spaghetti is a small solid rods, vermicelli is a tiny rod and noodles are flat strips. Pasta products are also available in the shapes of shells and alphabets. Pasta products are made from coarser durum wheat except noodles are made from wheat flour. Other materials used are groundnut meal, soya flour and cassava flour. The preparation can be enriched by addition of vitamin and amino acids. c. DEVELOPMENT OF VERMICELLI *Method Ingredients required

The maida flour was steamed for 5 minutes and conditioned by adding the required quantity of water and salt. The mixture was fed into the extruder by selecting the die (vermicelli). The dough was extruded. The extruded vermicelli were steam cooked for 5-10 minutes and dried at 60 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Special Technologies | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

d. DEVELOPMENT OF SPAGHETTI AND MACARONI Method

The maida flour was steamed for 5 minutes and conditioned by adding the required quantity of water and salt. The mixture was fed into the extruder by selecting the die (spaghetti and macaroni). The dough was extruded. The extruded spaghetti and macaroni were steam cooked for 5-10 minutes and dried at 60 PREPARATION OF NUTRIENT ENRICHED EXTRUDED PRODUCTS **Method Ingredients

The wheat flour and defatted soya flour was mixed thoroughly. The flour was steamed for 5 minutes and conditioned by adding the required quantity of water and salt. The dough was prepared and extruded through an extrude. The noodles were steam cooked for 5-10 minutes and dried at 60 PREPARATION OF EXTRUDED PRODUCTS UTILIZING COMPOSITE FLOUR MIX ** Preparation of noodles Ingredients

Mixed pulse flour The ground pulse flour (Bengal gram, green gram and peas) were mixed in the proportion of 1:1:1 to prepare mixed pulse flour. Method

SUITABILITY OF THE DEVELOPED EXTRUDED PRODUCTS FOR THE PREPARATION OF SAVOURY AND SWEET ITEMS SAVOURY

Ingredients needed

Method: The oil was heated in a frying pan and the mustard was added and allowed to crack. Then the black gram and bengal gram dhal, onion, green chillies and curry leaves were added to it. When the onion turned to golden yellow colour, required amount of water was added and boiled. Extruded product and salt were added to the boiling water and stirred. Cooking was continued till the sample became soft. 2. Curd bath Ingredients needed

Method: Extruded product was steam cooked and kept aside. Green chillies and ginger were cut into pieces. Seasoning was done using oil, mustard, green chillies and curry leaves and mixed with the curd. The cooked sample was added to curd, mixed well and served. 3. Tomato bath: Ingredients needed

Method: Sample was steam cooked and kept aside. To the heated oil the spices and finely chopped onion, green chillies, tomato and salt was added and continued cooking for 5 minutes. The cooked sample was added and mixed well. 4. Lime bath: Ingredients needed

Method: Cooked sample was seasoned with mustard, bengal gram dhal and chillies. Lime juice, salt and turmeric powder were added and mixed well. SWEET 1. Sweet product Ingredients needed

Method The sample was steamed in the idli steaming vessel for 15 minutes.Before serving, ghee, coconut scraping and sugar were mixed with the steamed noodle. Payasam Ingredients needed

Method: Milk was boiled and sugar was added followed by slightly roasted sample was added to it and cooked well. Cashew and raisin (ghee) and powdered cardamom was added. Continued cooking for 5 minutes and served hot. PREPARATION OF VERMICELLI WITH CARROT, AMARANTHUS, CURRY LEAVES AND MULLUMURUNKAI **

PREPARATION OF VERMICELLI WITH SPICES **

a. PROCESSING OF CAKE FROM THE FRUIT BASED EGG LESS INSTANT CAKE MIX

b. PREPARATION OF RAVA DOSA MIX * Dosa is a fermented product used in India. This is usually prepared from a fermented batter of rice and pulse in the proportions ranging from 6:1 to 10:1. Both the ingredients are finely ground, unlike the idli batter, which contains the rice component in a coarse consistency. The dosa batter is very thin and dosa is baked on a hot pan. A number of varieties of dosa can be prepared in hotels and uses. Among those masal dosai, onion dosai and rava dosai are highly popular irrespective of all the age groups.

Procedure Preparation of rice flour The parboiled rice – IR –20 was soaked in water for 5 hours. Then the water was drained completely and dried in solar drier for 5 hrs. The dried rice was ground in a mixie and sieved through BS 36 sieve. Materials required Rice flour, maida, semolina (white ravai), salt, cumin, citric acid, dehydrated green chillies.

Method All the ingredients were mixed thoroughly and packed in an airtight container for future use. Preparation of rava dosa For one part (measure) of instant rava dosa mix two part (measure) of water was added and mixed well. The prepared batter was allowed to stand for 30 min at room temperature before preparing dosa. The dosa tava was heated and oil / ghee was smeared it well. One cup of batter was spread on the tava and baked on both the sides by using low flame. c. Bombay Halwa Mix *Ingredients

Method All the ingredients are dried in a cabinet drier at 80 Preparation of Bombay halwa For one measure of the mix (100 g), add two measures of water (200 ml), 2 measures of sugar (200 g) and mix well. Cook the mix after adding dalda (or) ghee (50 g) for 20 minutes by stirring continuously. At the end add the broken cashewnuts (5 g), and melon seeds (5 g). Pour into a greased plate, allow it to cool and cut into pieces.

Method Mix Maida and corn flour and sieve it thoroughly. Later add milk powder again seive it thoroughly. Add powdered cardamom and required food colour and mix it and store it in the cool air tight container. Procedure Whenever in need add water and Instant Halwa Mix in the ration of 1:1, pour it in the kadai well stir when it thicken add ghee and cardamom, stir well until ghee oozes out from halwa. e. PREPARATION OF SWEETMEAT – BOLI *

Technologies Available * - Post Harvest Technology Centre, TNAU, Coimbatore. ** - Home Science College and Research Institute, TNAU, Madurai. Source

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Home | About Us | Success Stories | Farmers' Association | Farmers' Innovation | Publications | FAQs | Contact

© 2008-10 TNAU. All Rights Reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ingredients required

Ingredients required 1. Uppuma

1. Uppuma