QUALITY SEED PRODUCTION IN COTTON VARIETIES

Land Requirement

- Land should be free of volunteer plants.

- The previous crop should not be the other varieties of the same crop. It can be the same variety, if it is certified as per the procedures of certification agency.

Field Standards

A. General Requirements

Isolation

-

Cotton seed production fields should be isolated from the contaminants by allowing the isolation distance as specified below.

Contaminants |

Minimum distance (meters) |

Foundation |

Certified |

Fields of other varieties |

50 |

30 |

Fields of the same variety not conforming to varietal purity requirements for certification |

50 |

30 |

Fields of other varieties of different spp. (different ploidy levels) |

5 |

5 |

B. Specific requirements

Factor

|

Maximum permitted (%)* |

Foundation |

Certified |

Off-types |

0.10 |

0.20 |

*Maximum permitted during inspection at and after flowering.

Seed rate

- Seed rate varies with variety, naked seed, fuzzy seed and delinted seeds.

Factor

|

Maximum permitted (%)* |

Fuzzy seed |

Delinted |

Naked seed |

MCU 5, MCU 7, CO 14, CO 17, SVPR 2, SVPR 4, SVPR 6 |

6 |

3.0 |

- |

KC 3, K12 |

8.0 |

6.0 |

- |

Suvin |

- |

- |

2.4 |

Seed treatment

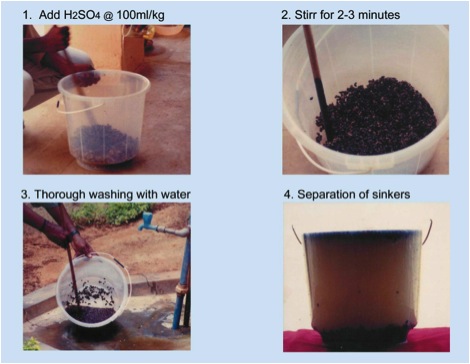

Acid-delinting of cotton seeds

-

Take plastic bucket for acid delinting of seeds.

-

Avoid using wooden drums, metal containers, porcelain items, or earthenware because the concentrated sulfuric acid will corrode them.

-

Place the required quantity of seeds in the plastic container and add commercial concentrated sulphuric acid at the rate of 100 ml /kg of fuzzy seed.

-

Stir vigorously and continuously with a wooden stick for 2 to 3 minutes till the fuzz on the seeds are completely digested and the seed coat attains a dark brown colour.

-

Add water into the bucket from the sideward to stop the delinting process. Drain the acid water and repeat the washing 4 to 5 times to remove any trace of acid.

-

Remove the floating, ill-filled and damaged seeds, and retain the healthy and good seeds which remain at the bottom.

-

Drain the water completely and dry the delinted seeds in shade.

Fuzzy seed

Delinted seed

Pre sowing seed treatment

- Coat the seeds with TNAU Vidhai Amirtham @ 11 ml / kg of seeds.

- Coat seeds with polymer @ 3 g / kg + imidachloprid @ 2 ml / kg + Pseudomonas fluorescens @ 10 g / kg + Azophos @ 120 g / kg of seed.

Field preparation and seed sowing

- Plough the field 3 to 4 times to attain fine tilth.

- Apply 5 tons of FYM or compost per acre uniformly before the last ploughing and incorporate and level the field.

- Improper leveling creates problem in irrigation which leads to differential flowering and there by the seed yield is reduced to a greater extent.

- Select the varieties suitable for the season.

- Form ridges by following variety specific spacing tabulated below.

- Sow the seed at 3 cm depth by adopting plant to plant spacing as below.

| Varieties |

Spacing between ridges (cm) |

Spacing between plants (cm) |

| MCU 5, CO 14, CO 17, Surabhi, SVPR 2, SVPR 4, SVPR 6 |

75 |

30 |

| KC 3, K 12 |

45 |

15 |

| Suvin |

90 |

45 |

Seed sowing

Seed sowing

The fertilizer recommended varies with varieties.

| Varieties / Hybrids |

Quantity of fertilizer (kg/ha) |

| |

N |

P205 |

K2O |

| MCU 7 |

60 |

30 |

30 |

| MCU 5, MCU 5 VT, MCU 9 |

80 |

40 |

40 |

| MCU 11, MCU 13 and Suvin |

80 |

40 |

40 |

| Jayalakshm, TCHB 213 HB 224 |

120 |

60 |

60 |

Fertilizer recommendation for different cotton varieties

|

Basal dose (kg/ha) |

Top dressing @ 40-45 days after sowing (kg/ha) |

|

N |

P |

K |

N |

P |

K |

| MCU 7 |

12 |

12 |

6 |

12 |

- |

15 |

| MCU 5, MCU 12, SVPR 2, CO 14, CO 17, SVPR 4, SVPR 6, Suvin, K12 |

16 |

16 |

8 |

16 |

- |

8 |

Earthing up

- Reform the ridges and furrows after first top dressing in such a way that the plants are in the center of ridges and well supported by soil.

Roguing

- Perform roguing at different stages of plant growth as detailed below.

| Stages of crop growth |

Characters to be observed |

Vegetative |

Height of the plant, colour of vegetation, leaf size, colour, shape and orientation, stem colour and diseased plants. |

| Flowering |

Leaf characters, flower characters like corolla colour, pollen colour, flower stalks, petal spot, bracts shape and pigmentation |

| Boll formation and harvesting |

Boll size, shape, colour, presence of beak, texture and pits. |

Foliar application of nutrients

- For better seed filling and more recovery, spray 1% DAP on 70, 80 and 90 DAS.

Methods to prevent shedding of squares and bolls

- To prevent square and boll shedding, spray 40 ppm NAA (Napthalene Acetic Acid) two times - first spray to be taken up at flowering stage and second spray after a month of first spray.

Square shedding

Square shedding

Topping

- Remove the apical bud manually on 90th and 105th days after sowing to enhance the sympodial branch formation.

Harvesting

- Fully opened kapas harvested from four to six pickings should be used for seed purpose.

Kapas sorting

Importance of roguing

- Stained, discoloured, hard locks, unopened, pest and disease infested kapas should be removed.

Pest attacked Discoloured Hard locks

Pest attacked Discoloured Hard locks

Ginning

Seed drying

Seed processing

-

During seed processing, the immature, ill-filled, broken seeds of cotton, other crop seeds and inert matter are removed.

-

Grade the seeds based on density using specific gravity separator.

Specific Gravity Separator

Specific Gravity Separator

Pre-storage Seed treatment

- Treat the seeds with carbendazim @ 2 g / kg of seed to prevent seed borne diseases.

Seed storage

-

Store the seeds in gunny bags or cloth bags for short term storage (8-9 months) with the seed moisture content of 9-10%.

-

Store the seeds in polylined gunny bags for medium term storage (12-15 months) with the seed moisture content of 7-8%.

-

Store the seeds in 700 gauge polythene bags for long term storage (more than15 months) with the seed moisture content of less than 6%.

Seed Standards

Factors |

Standards for each class of seed |

Foundation |

Certified |

Pure seed (minimum) |

98.0% |

98.0% |

Inert matter (maximum) |

2.0% |

2.0% |

Other crop seeds (maximum) |

5/kg |

10/kg |

Weed seeds (maximum) |

5/kg |

10/kg |

Germination (minimum) |

65.0% |

65.0% |

Moisture (maximum) |

10.0% |

10.0% |

For vapour-proof containers (maximum) |

6.0% |

6.0% |

|