INSTANT MIXES

PREPARATION OF IDLI MIX

Instant idli mixes eliminate the traditional method of grinding of both the ingredients and the leavening is produced by the action of chemical leavening agents.

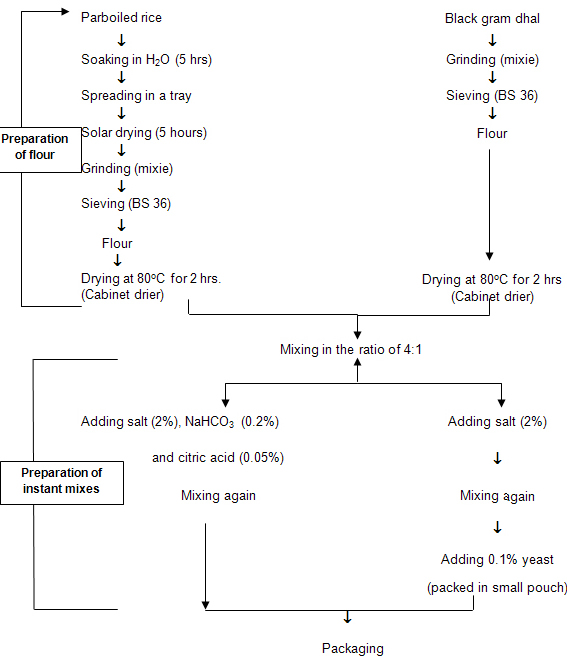

Preparation of rice and black gram flours

The parboiled rice IR 20 was soaked in water for 5 hours. Then the water was drained completely and dried in solar drier for 5 hrs. The dried rice was ground in a mixie and sieved through BS 36 sieve. Black gram dhal was also ground in a mixie and sieved (BS 36). The rice and black gram flour were dried in a cabinet drier at 80 for 2 hrs, cooled and packed in air tight containers till they were used. for 2 hrs, cooled and packed in air tight containers till they were used.

The parboiled rice IR 20 was soaked in water for 5 hours. Then the water was drained completely and dried in solar drier for 5 hrs. The dried rice was ground in a mixie and sieved through BS 36 sieve. Black gram dhal was also ground in a mixie and sieved (BS 36). The rice and black gram flour were dried in a cabinet drier at 80 for 2 hrs, cooled and packed in air tight containers till they were used. for 2 hrs, cooled and packed in air tight containers till they were used. |

|

Materials required

| Ingredients |

Volume (g) |

| Rice flour |

80 g |

Black gram dhal flour |

20 g |

Salt |

2 g |

Citric acid |

0.05 % |

NaHCO3 |

0.2% |

Method

-

The ground rice and blackgram dhal flours were mixed at the ratio of 4:1.

-

The salt, citric acid and sodium bicarbonate were added and mixed thoroughly.

-

Another batch of instant mix was prepared by adding yeast (0.1%) without the addition of citric acid and sodium bicarbonate.

PREPARATION OF INSTANT IDIAPPAM MIX

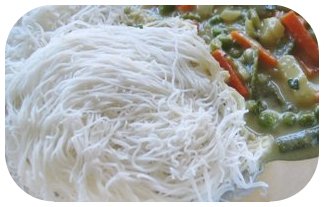

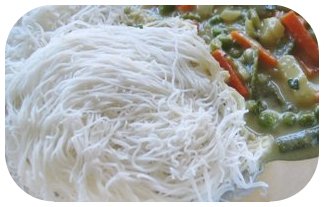

Idiappam is a traditional food prepared from the combination of parboiled rice and raw rice. It is consumed as breakfast / dinner for the peoples especially South Indians. It is a steamed product and consumed as either in the form of sweet or savoury dish (lime bath, tomato bath and curd bath).

Procedure

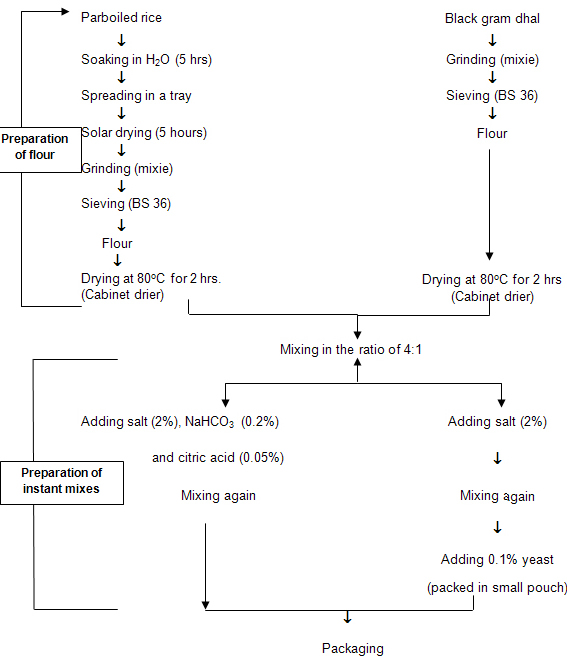

Preparation of rice flour

The parboiled rice – IR 20 and raw rice was soaked in water for 5 hours separately. Then the water was drained completely and dried in the solar drier for 5 hrs. The dried rice was ground in a mixie and sieved through BS 36 sieve.

|

|

Materials required

| Ingredients |

Volume (g) |

| Parboiled rice flour |

50 |

| Raw rice flour |

50 |

| Salt |

2 |

Method

Mix all the ingredients and stored, in the polythene bag.

Preparation of idiappam

The idiappam mix (100 g) was steamed in a steaming unit for 5 minutes (idli cooker). To the steamed flour, required quantity of boiling water (90 , 120 ml) was added and made into dough. The dough was extruded through hand noodle press, steamed in the idli cooker for 10 minutes. The prepared idiappam was organoleptically evaluated. , 120 ml) was added and made into dough. The dough was extruded through hand noodle press, steamed in the idli cooker for 10 minutes. The prepared idiappam was organoleptically evaluated.

PREPARATION OF MURUKKU INSTANT MIX

Method

Raw rice and black gram were ground in a mill separately and sieved through 80 BS sieve and used for the preparation of murukku instant mix.

Ingredients

| Ingredients |

Volume (g) |

| Rice flour (%) |

90 |

| Black gram flour (%) |

10 |

| Salt (g) |

2 |

| Water (ml) |

92 |

| White sesame seed |

5 |

The crispy mix was prepared by mixing raw rice flour, black gram dhal flour, salt and sesame seed. The mix was passed through 80 BS sieve for uniform mixing.

Method for the preparation of murukku

The dough was prepared by the addition of hydrogenated fat –5 g and water and extruded in a hand extruder of local make with 4 mm diameter orifice and fried in the heated oil at 180 for 3-5 minutes. for 3-5 minutes.

|

|

PREPARATION OF VADAGAM

Vadagam is a traditional product mostly prepared from rice flour and also sago. It is a deep fat fried product and consumed as a side dish in the meals

Preparation of vadagam

Materials required

Raw rice flour, green chillies, cumin seeds and salt.

| Ingredients |

Volume (g) |

| Rice flour (%) |

100 g |

| Green chillies |

1.5 g |

| Cumin seeds |

4.0 g |

| Salt |

2.0 g |

Method

The ingredients were mixed and 250 ml of water was added and cooked for 10 minutes until a thick extrudable paste was formed. The hot paste was extruded in hand extruder (dia 5 mm) and dried in sun for about five hours. The dried vadagam sample was packed in a polyethylene bags and sealed.

Frying of vadagam

Dried rice vadagam was fried in the refined oil at 180 for 40 seconds. The vadagam was organoleptically evaluated. for 40 seconds. The vadagam was organoleptically evaluated. |

|

|