|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Crop Production |

Major Areas :: Seed :: Seed Sampling |

Weather |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Objectives

Definitions of samples The seed lots received by laboratory for analysis and testing are given an accession number of each variety for future reference. Seed lot: Seed lot is a specified quantity of the seed of one cultivar of known origin as physically identifiable. Methods of sampling 1. Hand sampling This is followed for sampling the non free flowing seeds or chaffy and fuzzy seeds such as cotton, tomato, grass seeds etc., In this method, it is very difficult to take samples from the deeper layers of bag. To over come this, bags are emptied completely or partly and then seed samples are taken. While removing the samples from the containers, care should be taken to close the fingers tightly so that no seeds escape. 2. Sampling with triers/Probe By using appropriate triers, samples can be taken from bags or from bulk. The triers are used for taking free flowing seed samples. a). Bin samplers Used for drawing samples from the lots stored in the bins. b). Nobbe Trier The name was given after the father of seed testing Fredrick Nobbe. This trier is made in different dimensions to suit various kinds of seeds. It has a pointed tube long enough to reach the centre of the bag with an oval slot near the pointed end. The length is very small. This is suitable for sampling seeds in bag not in bulk. c). Sleeve type triers or stick triers It is the most commonly used trier for sampling: There are two types viz., I. With compartments 2. Without compartments. It consists of a hollow brass tube inside with a closely fitting outer sleeve or jacket which has a solid pointed end. Both the inner tube as well as the outer tube have been provided with openings or slots on their walls. When the inner tube is turned, the slots in the tube and the sleeve are in line. The inner tube mayor may not have partitions. This trier may be used horizontally or vertically. This is diagonally inserted at an angle of 30°C in the closed position till it reaches the centre of the bag. Then the slots are opened by giving a half turn in clockwise direction and gently agitated with inward push and jerk, so that the seeds will fill each compartment through the openings from different layers of the bag, then it is again closed and with drawn and emptied in a plastic bucket.

Sleeve type triers Method of preparing composite samples

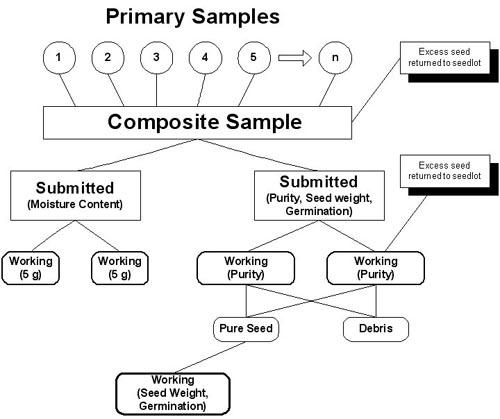

Types of sampling 1. Primary sample Each probe or handful of sample taken either in bag or in bulk is called primary sample. 2. Composite sample All the primary samples drawn are combined together in suitable container to form a composite sample. 3. Submitted sample When the composite sample is properly reduced to the required size that to be submitted to the seed testing laboratory, it is called submitted sample. Submitted sample of requisite weight or more is obtained by repeated halving or by abstracting and subsequently combining small random portions 4. Working sample It is the reduced sample with required weight obtained from the submitted sample after repeated mixing and dividing with which the seed quality tests are conducted in seed testing laboratory.

Sampling intensity The intensity of sampling should be maintained in accordance to the rules described by ISTA. When seeds are stored in bags or other containers of similar capacity that are uniform in size. a. For seed lots in bags (or container of similar capacity that are uniform in size) up to 5 containers Sample each container 31-400 containers Sample atleast one in every 5 containers 401 or more Sample atleast one in every 7 containers When the seed is in small containers such as tins, cartons or packets a 100 kg weight is taken as the basic unit and small containers are combined to form sampling units not exceeding this weight e.g. 20 containers of 5 kg each. For sampling purpose each unit is regarded as one container. b. For seeds in bulk Up to - 500 kg Atleast 5 Primary samples 501 - 3000 Kg One primary sample for each 300 kg but not less than 5 primary samples 3001-20,000 Kg One primary sample for each 500 kg but not less than 10 primary samples 20,001 and above One primary sample for each 700 kg but not less than 40 primary samples Instructions for sending samples Pre-requisite in sampling is that the seed lot received in containers / bags must be properly sealed and marked for identification with a single lot designation. At the time of sampling, all the samples drawn must bear identification corresponding to that of the lot certificate. The sampler should seal or supervise the sealing of the sample container / bags after drawing sample. After taking samples which may be more than required for seed testing purpose, a through mixing of the samples is to be done. Divide it using a seed divider and then the required amount should be submitted to the seed testing laboratory after putting proper identification mark. If mechanical divider is not available at the spot, a representative sample should be obtained by putting the entire quantity of seed on a clean floor, mixing properly and halving the sample until the desired quantity is obtained. For moisture determination, 100g of seeds for species which need grinding and 50g for all other species. Sample should be submitted in an air-tight container, like polythene bags of 700 guage or glass bottle with tight cap to the laboratory. Quantity and dispatch of sample for testing Weight of submitted sample The minimum weight for submitted samples for various tests are as follows. 1. Moisture test 100 gm for those species that have to be ground and 50 gm for all other species. 2. For verification of species and cultivar

Despatch of submitted sample

Types of sample used in Seed Testing Laboratory (STL) Service sample: Sample received from other than seed certification agencies and seed inspectors For other tests like purity and count of other species

Source: M. Bhaskaran et al.2003.Text book of “Principles of seed production and quality control”. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Special Technologies |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Home | About Us | Success Stories | Farmers Association | | Gallery | Message Board | TNAU Publications | FAQ’s | Queries | Downloads | Site Map | Disclaimer | Contact | |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

© All Rights Reserved. TNAU-2008. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||