|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Crop Production |

Major Areas :: Seed :: Seed Testing |

Weather |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Role of Seed Testing Laboratories (STL) Seed testing is determining the standards of a seed lot viz. physical purity, moisture, germination and ODV and thereby enabling the farming community to get quality seeds. The Seed Testing Laboratory is the hub of seed quality control. Seed testing services are required from time to time to gain information regarding planting value of seed lots. Objective & Importance of Seed Testing Seed testing is required to achieve the following objectives for minimising the risks of planting low quality seeds. Impotance

Role of Seed Testing Laboratories Seed testing laboratories are essential organization in seed certification and seed quality control programmes. The main objective is to serve the producer, the consumer, the seed industry by providing information on seed quality. Test results may cause rejection of poor seed multiplication or low grade seed in a count of law. Analysis of seed in the laboratory : Seed testing is possible for all those who produce, sell and use seeds.Seed testing is highly specialized and technical job. With a view to maintain uniformity in quality control the seed analysts laboratory includes for distinct sections. 1. Section for purity testing: Purity analysis of seed lot is considered under two factors.

2. Section for moisture testing Sampling in Seed Testing Laboratory The seed samples received in the laboratory (submitted sample*) are required to be reduced to obtain working samples for carrying out various tests. A number of methods are available for obtaining working samples.

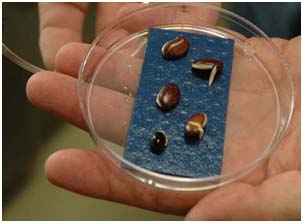

Model seed samples received from producer Mixing and dividing of seeds The main objective of mixing and dividing of seeds is to obtain the representative homogenous seed sample for analysis by reducing the submitted sample to the desired size of working sample. Method of mixing and dividing

Mechanical method The reduction of sample size is carried out by the mechanical dividers suitable for all seeds except for chaffy and fuzzy seeds. Objective of mechanical dividing

Types of mechanical dividers

Random cup method This is the method suitable for seeds requiring working sample upto 10 grams provided that they are not extremely chaffy and do not bounce or roll (e.g.) Brassica spp. Six to eight small cups are placed at random on a tray. After a preliminary mixing the seed is poured uniformly over the tray. The seeds that fall into the cup is taken as the working sample. Modified halving method The apparatus consists of a tray into which is fitted a grid of equal sized cubical' cups open at the top and every alternate are having no bottom. After preliminary mixing the seed is poured evenly over the grid. When the grid is lifted, approximately half the sample remains on the tray. The submitted sample is successively halved in this method until a working sample size is obtained. Spoon method This is suitable for samples of single small seeded species. A tray, spatula and a spoon with a straight edge are required. After preliminary mixing, the seed is poured evenly over the tray. The tray should not be shaked thereafter. With the spoon in one hand, the spatula in the other and using both small portions of seed from not less than 5 random places on the tray should be removed. Sufficient portions of seed are taken to estimate a working sample approximately but not less than the required size. Hand halving method This method is restricted to the chaffy seeds. The seed is poured evenly on to a smooth clean surface and thoroughly mixed into a mound. The mound is then divided into 1/2 and each half is mound again and halved into 4 portions. Each of the 4 portions is halved again giving 8 portions. The halved portions are arranged in rows and alternate portions are combined and retained. The process is repeated until the sample of required weight is obtained. Purity analysis The purity analysis of a seed sample in the seed testing laboratory refers to the determination of the different components of the purity viz., pure seeds, other crop seeds, weed seeds and inert matter. Objective The objective of the purity analysis is to determine whether the submitted sample conforms to the prescribed physical quality standards with regard to physical components. Method The working sample The purity analysis is done on the working sample of prescribed weight drawn from submitted sample. The analysis may be made on one working sample of the prescribed weight or on two sub-samples of atleast half of this weight, each independently drawn. Weighing the working sample The number of decimal places to which the working sample and the componenets of the working sample should be weighed is given below.

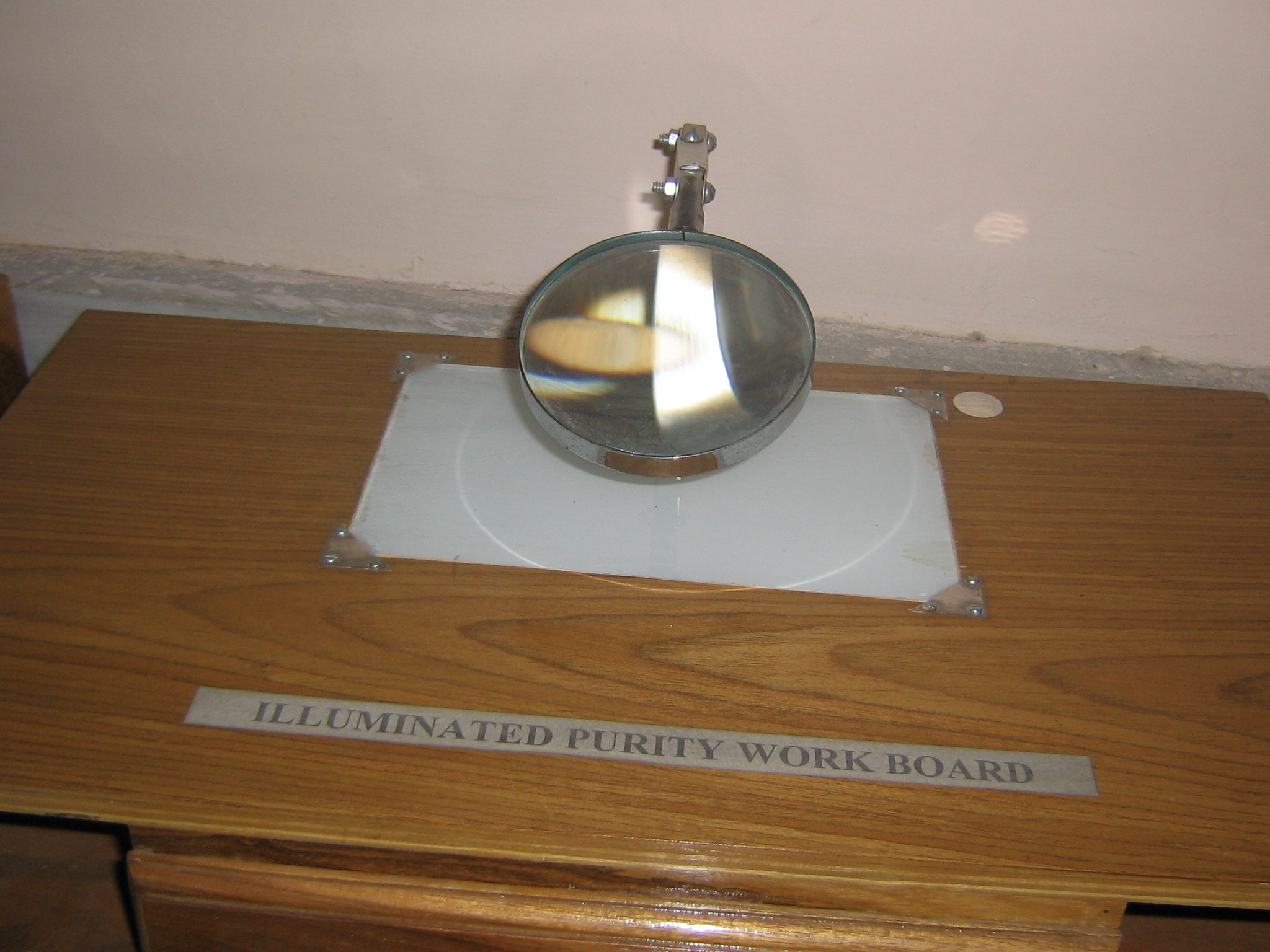

Purity separation The working sample after weighing is separated into its components viz., pure seed, other seed crop, weed seed and inert matter. Pure seed The seeds of kind / species stated by the sender. It includes all botanical varieties of that kind / species. Immature, undersized, shrivelled, diseased or germinated seeds are also pure seeds. It also includes broken seeds, if the size is >1/2 of the original size except in leguminaceae, and cruciferae where the seed coat entirely removed are regarded as inert matter. Other crop seed It refers to the seeds of crops other than the kind being examined. Weed Seed It includes seeds of those species normally recognized as weeds or specified under Seed Act as a noxious weed. Inert matter It includes seed like structures, stem pieces, leaves, sand particles, stone particles, empty glumes, lemmas, paleas, chaff, awns, stalks longer than florets and spikelets. Method of purity separation Place the sample on the purity work board after sieving / blowing operations and separate into other crop seeds and inert matter. After separation, identify each kind of weed seeds, other crop seeds as to genus and species. The names and number of each are recorded. The type of inert matter present should also be noted.

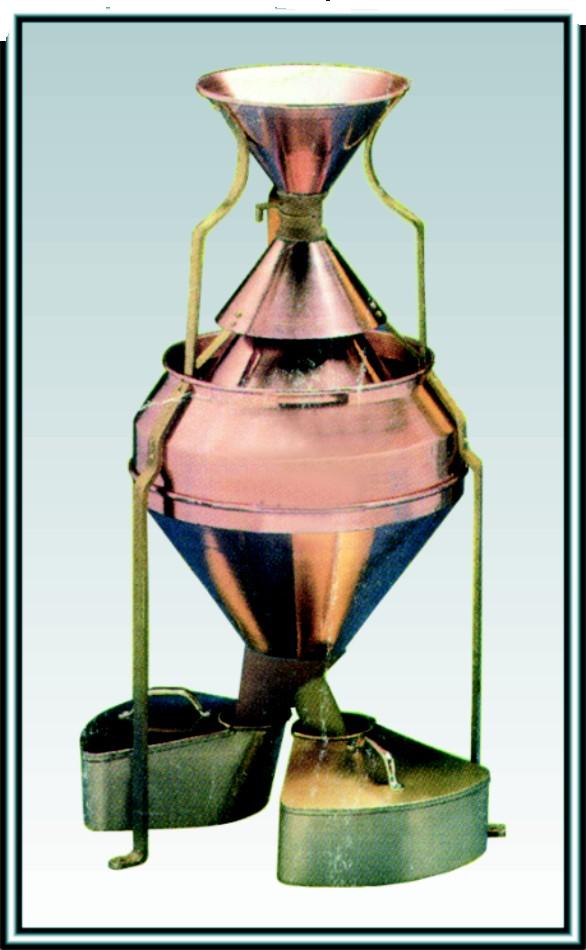

Seed Blower

Purity Work Board

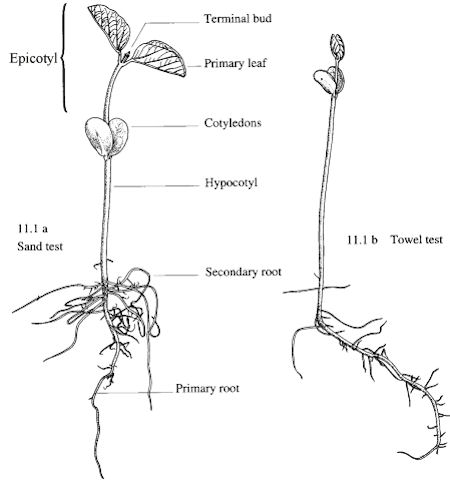

Calculation All the four components must be weighed to the required number of decimal places. The percentages of the components are determined as follows. Duplicate tests Analysis result near the border line in relation to the seed standards, one more test is done and the average is reported. However, if a duplicate analysis is made of two half sample or whole samples, the difference between the two must not exceed the permissible tolerance. If the difference is in excess of the tolerance, analyze further (but not more than 4 pairs in all) until a pair is obtained which has its member within tolerance. Purity analysis in groundnut It should be carried out on pods and the size of working sample is 1000. Determination of huskless seeds It is required in certain crops like sunflower and paddy. 400 Germination is defined as the emergence and development from the seed embryo, of those essential structures, for the kind of seed in question, indicates its ability to produces a normal plant under favourable conditions. Principles Germination tests shall be conducted with a pure seed fraction. A minimum of 400 seeds are required in four replicates of 100 seeds each or 8 replicates of 50 seeds each or 16 replicates of 25 seeds each depending on the size of seed and size of containers of substrate. The test is conducted under favourable conditions of moisture, temperature, suitable substratum and light if necessary. No pretreatment to the seed is given except for those recommended by ISTA. Materials required The substratum serves as moisture reservoir and provides a surface or medium for which the seeds can germinate and the seedlings grow. The commonly used substrate are sand, germination paper and soil. 1. Sand Size of sand particle Sand particles should not be too large or too small. The sand particles should pass through 0.80 mm sieve and retained by 0.05mm sieve. Toxicity Sand should not have any toxic material or any pathogen. If there is presence of any pathogen found then the sand should be sterilized in an autoclave. Germination tray When we use the sand, germination trays are used to carry out the test. The normal size of the tray is 22.5 x 22.5 x 4 cm. The tray may either zinc or stainless steel.

Germination tray

Method of seed placement Seed in sand(S) Seeds are planted in a uniform layer of moist sand and then covered to a depth of 1 to 2 cm with sand.

Sand method Top of sand (TS) Seeds are pressed in to the surface of the sand. Spacing We must give equal spacing on all sides to facilitate normal growth of seedling and to avoid entangling of seed and spread of disease. Spacing should be 1-5 times the width or diameter of the seed. Water The amount of water to be added to the sand will depend on size of the seed. or cereals, except maize, the sand can be moistened to 50% of its water holding capacity. For large seeded legumes and maize sand is moistened to 60% water holding capacity. 2. Paper

Most widely used paper substrates are filter paper, blotter or towel (kraft paper). It should have capillary movement of water, at vertical direction (30 mm rise / min.). It should be free from toxic substances and free from fungi or bacteria. It should hold sufficient moisture during the period of test. The texture should be such that the roots of germinating seedlings will grow on and not into the paper. Methods Top of paper (TP) Seeds are placed on one or more layers of moist filter paper or blotter paper in petriplates. These petriplates are covered with lid and placed inside the germination cabinet. This is suitable of those seeds which require light.

Petriplate method Between paper (BP) The seeds are germinated between two layers of paper.

Germination apparatus Germination cabinet / Germination room This is called chamber where in temperature and relative humidity are controlled. We can maintain the temperature, relative humidity and light required for different crops. Room germinator It works with same principle as that of germinator. This is a modified chamber of larger one and the worker can enter into it and evaluate the seedlings. Provisions are made to maintain the temperature and relative humidity. This is used widely in practice.

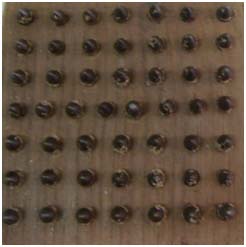

Seed counting board

Seed Counting Board Vacuum seed counter Consists of a head, pipe and wall. There are plates of 50 or 100 holes which can be fitted to the head. When vacuum is created the plate absorbs seeds and once the vacuum is released the seeds fall on the substrate.

Vacuum seed counter

Impression board Made of plastic / wood with 50 or 100 holes / pins. Here the knobs are arranged in equal length and space. By giving impression on the sand it makes uniform depth and spacing for seed.

Impression board The germination test is evaluated as

ISTA classified the seedlings into different categories based on the development of essential structures. Normal seedlings Seedlings which the capacity for continued development into normal plant when grown in favourable conditions of soil, water, temperature and light. Characters of normal seedlings

A well developed root system with primary root except in certain species of graminae which normally producing seminal root or secondary root. A well developed root system with primary root except in certain species of graminae which normally producing seminal root or secondary root.

Normal seedlings

Parts of seedlings

Abnormal seedlings Seedlings which do not show the capacity for continued development into normal plant when grown in favourable condition of soil, water, temperature and light.

Types of abnormal seedlings Damaged seedlings Seedligs with any one of the essential structures missing or badly damaged so that the balanced growth is not expected. Seedlings with no cotyledons, with splits, cracks and lesions or essential structures and without primary root.

Damaged seedlings

Weak or unbalanced development of essential structures such as spirally twisted or stunted plumule or hypocotyls or epicotyls, swollen shoot, stunted roots etc,

Twisted coleoptiles Decayed seedlings

Decayed Seedlings Hard seeds

Hard Seeds

Fresh and ungerminated seeds

Dead Seeds

Seeds at the end of the test period are neither hard or nor fresh or have produced any part of a seedling. Often dead seeds collapse and milky paste comes out when pressed at the end of the test.

Dead seeds Retesting If the results of a test are considered unsatisfactory it will not be reported and a second test will be made by the same method or by alternative method under the following circumstances. Use of tolerances The result of a germination test can be relied upon only if the difference between the highest and the lowest replicates is within accepted tolerances. To decide if two test results of the same sample are compatible again the tolerance table is used. Reporting results The result of the germination test is calculated as the average of 4x100 seed replicates. It is expressed as percentage by number of normal seedlings. The percentage is calculated to the nearest whole number. The percentage of abnormal seedlings, hard, fresh and dead seeds is calculated in the same way. These should be entered on the analysis of certificate under appropriate space. If the result is nil for any of these categories it shall be reported as ‘O’. Determination of moisture content Objective To determine the moisture content of seeds by methods suitable for routine use. Definition The moisture content of a seed sample is the loss in weight when it is dried. It is expressed as a percentage of the weight of the original sample. It is one of the most important factors in the maintenance of seed quality. Method of moisture determination 1. Air oven method In this method, seed moisture is removed by drying the seed sample at a specified temperature for a specified duration. 2. Moisture meters Moisture meters estimate seed moisture quickly but the estimation is not as precise as by the air-oven method. Weight of the submitted sample 100 gms for species that have to be ground. 50 gm for all other species. The sample should be submitted in polythene bag of 700 gauge. Air oven method for seed moisture estimation Materials required It should be constructed of non-absorbent material. It should grind evenly and should be operated at such a speed that during grinding, it should not cause heating of the ground material. Air currents that might cause loss of moisture must be reduced to a minimum. The fineness of grinding should be adjustable.

Grinding mill

Container Container of glass or non-corrosive metal (e.g.) stainless steel should be used. Oven A good quality electric air oven with a thermostatic electronic temperature control for maintaining temperature within ±1°C is required.

Oven Desiccator, Analytical balance, Sieves. A set of wire mesh sieves with meshes of 0.5 mm, 1.0 mm and 4.0 mm.

Grinding For some seeds (e.g. Cereals and Cotton) fine grinding is essential before the moisture content is determined. In such cases, at least 50% of the ground material should pass through a wire sieve with meshes of 0.5 mm and not more than 10% remain on a wire sieve with a mesh of 1.0 mm. For leguminous seeds, coarse grinding is recommended; at least 50% of the ground material shall pass through a wire sieve with meshes of 4.0 mm. Pre drying If the species is one for which grinding is necessary and the moisture content is more than 17%. (or 10% in the case of soy bean and 13% in rice) pre drying before grinding is necessary. For this purpose, two 50 gm portions are weighed and placed on open trays at 130°C for 5-10 min. If seed moisture content is about 25% or more it should be pre-dried at 70° C for 2-5 hours, depending on the initial water content. The pre dried seeds should be kept in a closed desiccator for cooling. Then each of the duplicate quantities is weighed separately and about 20 g is ground. The ground material is then subjected to moisture testing using a hot air-oven as described below. Moisture estimation It should be carried out in duplicate on two independently drawn 5-10 g working samples, weighed with an accuracy of 1 mg. Most species are dried for 1 hr at 130° C, cereals for 2 hours (130° C) and maize for 4 hours (130 °e). Seeds containing high percent- age of oil should be dried at 103°C for 17 hours.

F.G. : Fine grinding ; C.G. : Coarse grinding Steps m2-m3 Where, m = Seed moisture content S1xS2 Moisture meters: Universal (OSAW) digital moisture meters It consists of a compression unit to compress the sample to pre -determined thickness. The thickness setting is very easily read on a vertical and circular scale. The seed material on test is taken in a test cup and is compressed. Then press the push type switch till the reading comes in the display. Here no temperature reading and correlated dial are required. The computer version of digital moisture meter automatically compensate for temperature corrections.

Seed standards for moisture content

Top

The seed Samples received in the Seed Testing Laboratories are of three types. 1. Certification samples for certification purpuses on payment of Rs.20/sample by the producers as testing charges. 2. Official Samples for the Quality control Purpuses at government cost.This type of samples are drawn by the Seed Inpectors for the Quality Control as per the Seed Control Order and Seed Act to asure the availablity of Quality seeds to the farming community. 3. Sevice Samples for the farmers,Producers and Sellers on payment of cost @Rs.30/sample to know the seed standard of their seeds. This type of samples are drawn and sento the seedtesting lab.by the Farmers,Producers and the sellers to know their seed standards. Anybody including Farmers can Test their samples for it Standard before the seeds are being certified, sold or sown.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Special Technologies | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Home | About Us | Success Stories | Farmers Association | | Gallery | Message Board | TNAU Publications | FAQ’s | Queries | Downloads | Site Map | Disclaimer | Contact | |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

© All Rights Reserved. TNAU-2008. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The principle involved in these moisture meters is that wet grains are good conductors while dry grains are less conductors of electricity. So, the moisture content is directly proportional to the electrical conductivity of the seed.

The principle involved in these moisture meters is that wet grains are good conductors while dry grains are less conductors of electricity. So, the moisture content is directly proportional to the electrical conductivity of the seed.