|

|||||||||||||||||||

| Home | Seed Scheme | Seed Village Concept | Mega Seed Project | Related Links | FAQ's | Contacts | |

|||||||||||||||||||

Seed Processing |

Seed Processing :: Importance |

TNAU Seed Centre |

|||||||||||||||||

SEED PROCESSING

Principle of seed processing The processing operations are carried out based on the principle of physical differences found in a seed lot.

Requirement in seed processing

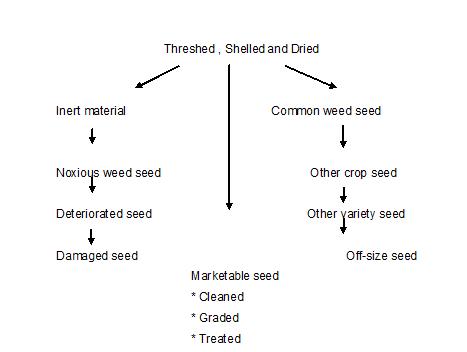

Types of materials removed during seed processing

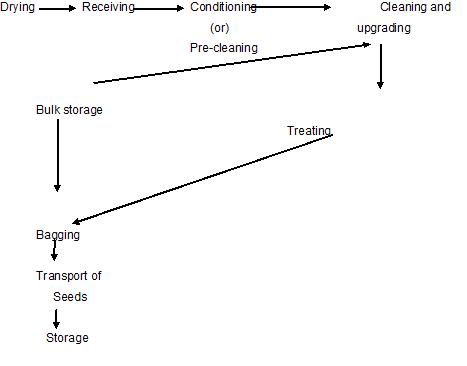

Sequence of operation in seed processing Sequence of operations are based on characteristics of seed such as shape, size, weight, length, surface structure, colour and moisture content. Because each crop seed possesses particular seed structure, the sequence of operation will be perfomed with proper equipments. It involves the following stages,

The flow charts illustrating the types of materials removed from harvested produce during processing. Harvested seed

Receiving The field run produce after threshing is received in the processing plant. Seed movement /basic steps in seed processing plant .

|

|||||||||||||||||||

Seed Treatments |

|||||||||||||||||||

Seed Certification |

|||||||||||||||||||

Seed Storage |

|||||||||||||||||||

| Home | Seed Scheme | Seed Village Concept | Mega Seed Project | Related Links | Gallary | FAQ's | Contacts | |

|||||||||||||||||||

| © All Rights Reserved. TNAU-2008. |

|||||||||||||||||||