|

Farm Implements

| Improved Direct Paddy Seeder |

|

| Function |

: |

For uniform seed distribution with respect to time and for maintaining uniform plant population per metre square |

| Specification |

: |

|

| Power requirement |

: |

Manually operated |

| Overall dimensions |

: |

2000 x 1500 x 640 mm |

| Weight |

: |

10 kg |

| Coverage, ha per day |

: |

1.1 |

General Information :

The unit consists of a seed drum, main shaft, ground wheel, floats, furrow openers and handle. The seed drum is hyperboloid shape (truncated cone) with 200 mm diameter having 12 mm flat spikes of 25 mm length kept parallel to the axis of rotation. The slopes of the cone facilitate the free flow of seeds towards the metering holes. Nine numbers of seed metering hole of 10 mm diameter were provided along the circumference of the drum at both the ends at a row-to-row spacing of 200 mm. Two floats were provided on either side to restrict the sinkage and to facilitate easy pulling of the unit. |

| Cost of the unit (approx) |

: |

Rs. 4800/- |

| Salient features |

: |

- Uniformity in seed sowing and plant population.

- Reduction in seed rate and the cost of thinning is reduced.

- Hill dropping of seeds is achieved and continuous drilling is eliminated.

|

|

|

|

| |

Top |

| |

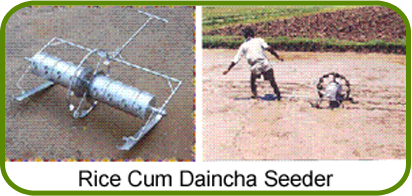

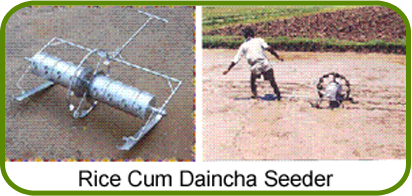

Rice Cum Daincha Seeder |

|

|

| Function |

: |

It sows paddy in 3 rows and green manure in 3 rows simultaneously. |

| Specification |

: |

|

| Power requirement |

: |

Manually operated |

| Overall dimensions |

: |

1650 x 1600 x 690 mm |

| Weight |

: |

15 kg |

| Coverage, ha per day |

: |

0.8 ha per day |

General Information :

The seeder has two drum hoppers , two skids, a ground wheel and a handle. Paddy seed rate can be adjusted from 72 – 75 kg per ha. The seeder simultaneously sows pre germinated paddy seeds and daincha seeds in alternate rows and puddled soil. The advantage of this seeder is avoidance of separate cultivation of green manure crop. |

| Cost of the unit (approx) |

: |

Rs. 6000/- |

| Salient features |

: |

- Uniformity in seed sowing and plant population.

- Reduction in seed rate and the cost of thinning is reduced

- Hill dropping of seeds is achieved and continuous drilling is eliminated.

- Growth of competitive weeds is checked due to green manure crop.

|

|

|

| |

Top |

| Rice Transplanter |

|

| |

| Function |

: |

For transplanting mat type paddy seedlings. Suitable for all transplanted type paddy varieties. |

| Specification |

: |

|

| Type |

: |

Manually operated |

| Power requirement |

: |

One operator and one labour to transport mat seedlings |

| Overall dimensions |

: |

1230 x 1250 x 835 mm |

| Weight |

: |

17 kg |

| Capacity |

: |

0.25 ha / day |

General Information :

The machine consists of a seedling tray, forks, handle and skids. By pressing the handle, the forks pick-up the seedlings and plant them in 6 rows. For every stroke of the handle the seedling tray moves side wards for uniform picking of seedlings by the forks. The operator has to pull the machine while punching the handle at the desired spacing. The Row to row spacing is 200 mm. |

| Cost of the unit |

: |

Rs. 7500/- |

| Salient features |

: |

| Planting can be done in 6 rows at a time. |

|

|

|

|

| |

Top |

| |

Seed cum Fertilizer Drill for Paddy |

|

| Function |

: |

For direct sowing of paddy and simultaneous application of fertilizer |

| Specification |

: |

|

| Type |

: |

Mounted implement |

| Power requirement |

: |

35 – 45 hp tractor |

| Capacity |

: |

3 ha/day |

| General Information |

: |

|

| Cost of the unit (Approx) |

: |

Rs.45000/- |

Salient features :

- The seed rate and fertilizer rate can be adjusted

- Can be operated by a 35 HP tractor

- By applying the required quantity of fertilizer at root zone, better crop growth and more yields is obtained.

- Saving in cost:65%

- Saving in labour:84%

- Cost of operation: Rs.800 / ha

|

|

|

| |

Top |

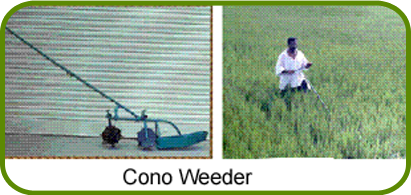

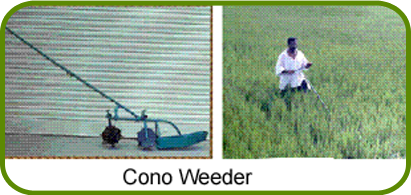

| Cono Weeder |

|

| Function |

: |

For weeding between rows of paddy crop |

| Type |

: |

Manually operated |

| Number of rotors |

: |

Two |

| Number of operators |

: |

One |

| Overall dimensions |

: |

37 cm x 1.4 m |

| Weight |

: |

5 to 6 kg |

General Information :

The cono weeder has two conical rotors mounted in tandem with opposite orientation. Smooth and serrated blades mounted alternately on the rotor uproot and burry weeds because the rotors create a back and forth movement in the top 3 cm of soil, the cono weeder can satisfactorily weed in a single forward pass without a push pull movement.

|

| Cost of the unit (approx) |

: |

Rs. 1500/- |

| Salient features |

: |

- Easy to operate by a single operator

- The weeder does not sink in puddled soil

- Field capacity 0.18 ha/day

|

|

|

|

| |

Top |

| |

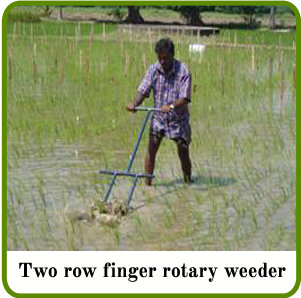

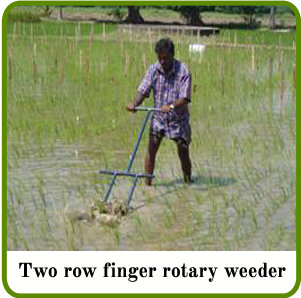

Two Row Finger Type Paddy Rotary Weeder |

|

| Function |

: |

For weeding in paddy row crops |

| Type |

: |

Manual operated |

| Power requirement |

: |

- |

| Capacity |

: |

0.35 ha / day |

| General Information |

: |

|

| Cost of the unit (Approx) |

: |

Rs.900/- |

Salient features

- Row spacing can be adjusted for 20cm and 25 cm

- One man can easily operate the unit continuously

- By push pull action the weeds are buried and soil aerated.

- Saving in cost :80%

- Saving in labour : 60%

- Cost of operation: Rs.250 / ha

|

|

|

| |

Top |

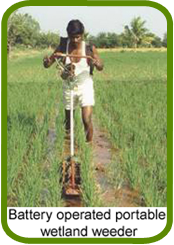

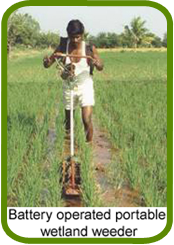

| Battery Operated Portable Wetland Weeder |

|

| Function |

: |

For weeding in SRI field |

| Specification |

: |

|

| Type |

: |

Manual operated |

| Power requirement |

: |

|

| Capacity |

: |

0.2 – 0.3 ha/day |

| General Information |

: |

|

| Cost of the unit (Approximate) |

: |

Rs.8000/- |

| Salient features |

: |

- Easy to operate compared to cono weeder

- Operated without experiencing any drudgery

- Weeding efficiency: 95%

- Cost of operation: Rs.625/ha

|

|

|

|

| |

Top |

| |

Self Propelled Vertical Conveyor Reaper |

|

| Function |

: |

For harvesting paddy |

| Overall dimensions (L x W x H), mm |

: |

2200 x 950 x 1100 |

| Type |

: |

Self propelled engine |

| Power requirement |

: |

3.0hp |

| Capacity |

: |

0.125 ha h-1 |

General Information

Vertical conveyor reaper (0.75 m) of TNAU is light in weight and hence shifting the reaper from one field to another is easy. Operating the reaper is fatigue free. The total cost of the machine is well within the purchasing power of the small farmers. It is highly cost economical when compared to other paddy harvesters and combine and manual harvesting. |

| Cost of the unit (Approx) |

: |

Rs.60,000 |

|

|

| |

Top |

| Paddy Reaper Harvester |

|

| Function |

: |

For harvesting and windrowing non-lodging paddy varieties. It is a self propelled unit and width of coverage is 0.75 m. |

| Specification |

: |

|

| Type |

: |

Self propelled |

| Power requirement |

: |

3 hp kerosene engine, 1 operator and 2 women labourers to collect and bundle the cut crop |

| Overall dimensions |

: |

2200 x 850 x 1170 mm |

| Capacity |

: |

1 ha / day |

General Information

The machine consists of gear box, ground wheels, handle, cutter bar assembly, star wheels and gathering header assembly. The crop should be manually harvested along the four sides of the field for a width of 0.5m and cleared from the field for providing space to the machine. At one corner an area of 2 x 1.5m should be manually harvested to place the machine initially in the field. Since the harvested crop is discharged at the right side of the reaper the harvested should be turned always to the left side. |

| Cost of the unit (approx) |

: |

Rs.1,00,000/- |

| Salient features |

: |

- Fuel consumption - 1 litre/ha

- Height of cut - 50 mm

- Labour - 1 operator and 2 women laboure (to collect and bundle the cut crop)

|

|

|

|

| |

Top |

| |

Mini Combine Harvester for Paddy |

|

| Function |

: |

For combined operations of Harvesting, threshing and winnowing |

| Specification |

: |

|

| Type |

: |

Self propelled |

| Capacity |

: |

1 ha / day |

| Cost of the unit (approx) |

: |

Rs.3,00,000/- |

| Cost of operation |

: |

Rs.1300 / ha |

| Special features |

: |

- Suitable for small and marginal farmers

- Can be easily transported to inaccessible fields

- Saving in cost: 80%

- Saving in labour: 91%

|

|

|

| |

Top |

| Manually Operated Fertilizer Broadcaster |

|

| Function |

: |

For broadcasting granular fertilizers like urea, DAP etc in the field uniformly. |

| Type |

: |

Manually operated |

| Power source |

|

One person |

| Hopper bottom shaped |

: |

Cone |

| Length (mm) |

: |

280 |

| Width (mm) |

: |

410 -415 |

| Height (mm) |

: |

441 -450 |

| Hopper capacity (kg) |

: |

12-15 |

| Shape of metering hole |

: |

circular |

| Spreading disc spinner diameter, (mm) |

: |

225 -273 |

| Vertical clearance from hopper bottom(mm) |

: |

24 -44 |

| No of fins |

: |

8 |

| Weight (kg) |

: |

3.8 -10 |

General Information

It consists of a hopper with tapered bottom, with a side slope of about 46 degrees. A circular disc having X sections is fitted on a vertical shaft below the fertilizer hopper and is rotated by a handle through gear arrangement. The gear ratio between the handle and the spreading disc is 1:8.4. A metered quantity of the fertilizer through adjustable opening falls on the disc, which spreads uniformly due to centrifugal force. Machine is mounted on the shoulders and is operated at a forward speed of about 2.0 km/h. |

|

|

|

| |

Top |

| |

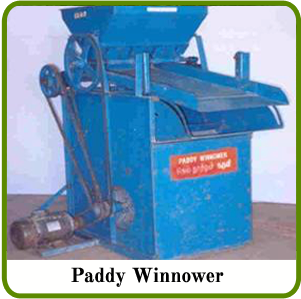

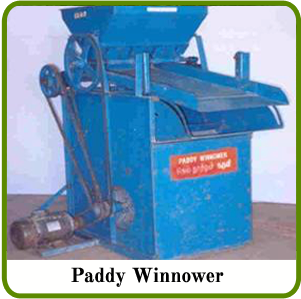

Paddy Winnower |

|

| Function Specifications |

: |

Cleaning of paddy by winnowing |

| Type |

: |

Power operated, continuous |

| Overall dimensions |

: |

1,210 mm x 960 mm x 1,430 mm |

| Test Results |

|

|

| Suitability for crops |

: |

Paddy |

| Capacity |

: |

7.5 q/h |

| Power requirement |

: |

1 ha electric motor |

| Labour requirement |

: |

Two |

| Winnowing efficiency |

: |

97% |

| Cost of equipment |

: |

Rs. 7,000 |

|

Salient Features

The machine winnows paddy already threshed by the paddy thresher or by other means. It has a feeding hopper at the top to receive the threshed paddy, chaff and straw bits. A blower provided at the bottom sends a stream of air which separates the straw, chaff and other impurities. The dust, chaff and straw come out through an opening and cleaned paddy is taken out through another spout. |

|

| |

Top |

| Household Paddy Parboiling Unit |

|

| Function |

: |

To parboil paddy uniformly |

| Specification |

|

|

| Overall dimension (D x H ) mm |

: |

650 x 900 |

| Capacity |

: |

125 kg/batch |

| Power required |

: |

5 kg of firewood/batch |

General Information

The parboiling drum is made of galvanized iron sheet of 20 gauge thickness with a lid. The drum is divided into three equal portions. The top two-third portion retains paddy for parboiling and bottom one-third portion holds water to produce steam for parboiling. A perforated slanting sheet with perforated pipes separates the steam chamber from parboiling chamber. The lateral perforated pipes attached to the main steam pipe divides the entire parboiling chamber into a number of small compartments and helps for uniform and simultaneous parboiling of paddy. Perforated sloping floor helps for natural unloading of parboiled paddy. The water in the drum can be heated by burning firewood or any agricultural waste. After the completion of parboiling, the remaining hot water can be used for next batch. |

| Cost of the unit (approx) |

: |

Rs.4,500/- |

| Cost of operation |

: |

Rs.7/h |

| Salient features |

: |

- Uniform parboiling and increased head rice recovery is possible.

- Times 45 minutes for parboiling the first batch of soaked paddy and 25 minutes for the subsequent batches.

- It can also be used as a storage bin, when not used for parboiling.

|

|

|

|

| |

Top |

| |

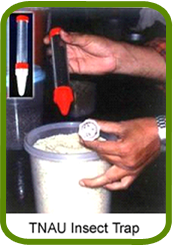

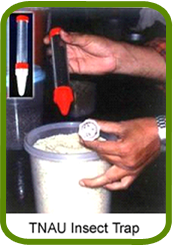

TNAU Insect Trap |

|

| Function Specifications |

: |

To utilize cir pith for the production of particle board |

overall dimensions (L x B x H )

|

: |

27 mm diameter and 150 mm long |

| Capacity |

: |

Suitable for a bin holding upto 25-50 kg |

| Power requirement |

: |

1 ha electric motor |

| Labour requirement |

: |

Two |

| Winnowing efficiency |

: |

97% |

| Cost of equipment |

: |

Rs. 7,000 |

General Information

The basic characteristics of the stored product insects, viz., affinity towards air, tendency to move towards aerated region, wander in the grain and active during dusk and dawn have been exploited in the development of the trap. The stored grain insects, like red flour beetle, saw toothed beetle, rice weevil, paddy moth, turmeric beetle, drug beetle, pulse beetle, groundnut bruchid, dermestid beetles, flat grain beetles, etc with the behaviour of wandering in the bulk grain, reach the insect trap. These insects will enter the trap through the perforations and reach the stem of the trap. In the stem, as the insects cannot move upward and escape, they move towards the bottom and reach the pit fall placed at the bottom.

|

| Cost of the unit (approx) |

: |

Rs.75/- |

| Salient features |

: |

- Suited only for bin storage.

- 2 or 3 traps can be placed at 15 to 20 cm depth in a bin of 30 to 45 cm diameter and 25 kg capacity for maximum benefit.

- No insecticide is used in this trapping technique.

- Easy to handle and maintenance free.

|

|

|

| |

Top |

|