VALUE ADDITION

1. VALUE ADDED PRODUCTS FROM PULSES

Top

a. ROASTING OF PULSES OR PUFFED LEGUMES **

Puffed Chickpea and Peas

Puffed chickpea and peas are widely used in India as a snack.

Procedure

1. Soaking chickpea or peas in water for a 15-20 minutes and draining of water

2. Keeping the wet grains in a closed vessel for the moisture to equilibrate in the grain

3. Puffing the wet grains in a hot iron vessel containing sand at 190-200 for 60-80 sec. for 60-80 sec.

4. The grains puff and the husk is split off

For efficient puffing, the temperature just before explosion must be sufficient to create a high enough water vapour pressure without burning the pericarp and the temperature increase must be fast enough to build up the required pressure before the water evaporates. Moisture content of the kernel has a pronounced effect on popping behaviour. The kernels, which are too dry, often pop up feebly.

Parching of pulses

Legumes such as Bengal gram and peas are parched to give highly acceptable products. Bengal gram is tied in a moist cloth and kept overnight before it is parched. Peas are soaked in water for 5 minutes dried partially in the sun for 15 minutes and then parched. Salt and turmeric powder are sometimes added to the steeping water or the grains smeared with the paste of the same before they are parched. Parching is done in a hot iron vessel containing sand at 190-200 for 60-80 seconds. Parching Bengal gram has been used in the treatment of protein calorie malnutrition in children for 60-80 seconds. Parching Bengal gram has been used in the treatment of protein calorie malnutrition in children

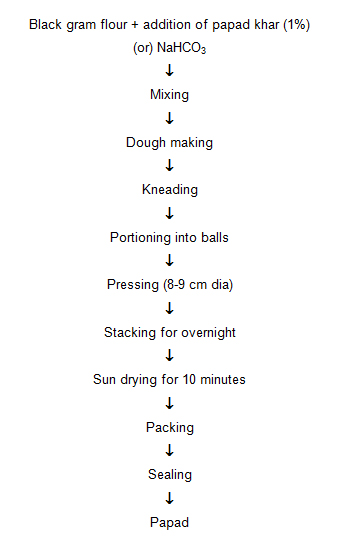

b. PREPARATION OF PAPAD **

Papad also known as appalam or papadam in South India, is essentially a thin wafer like product, usually circular in shape rolled from a dough made out of pulse, cereals, edible vegetable oil, alkaline and mucilaginous additives. It is normally consumed in toasted or fried form. In India, papad has been associated and deeply entwined with social customs/ rituals and has been developed into culinary art.

Materials needed

| Black gram flour |

100g |

Water |

50 ml |

Salt |

7 g |

Sodium bicarbonate

(or) sodium carbonate |

1 g |

Asafoetida |

0.2 g |

Refined oil |

2-3 g |

Method

All the ingredients except water were mixed well. The dough was prepared after adding water. The prepared dough was kneaded well and divided into balls of 15 gm each and pressed to 0.8 cm thickness with 8-9 cm diameter papad. The papad was soaked overnight, conditioned and dried under the sun for 10 minutes to reduce the moisture content to + 14.0 per cent. It was packed in polyethylene pouches. The steps involved in the processing of papad are given below: |

Frying of papad

Dried papad was fried in the refined oil at 195 for 5 to 7 seconds. The papad was organoleptically evaluated. for 5 to 7 seconds. The papad was organoleptically evaluated.

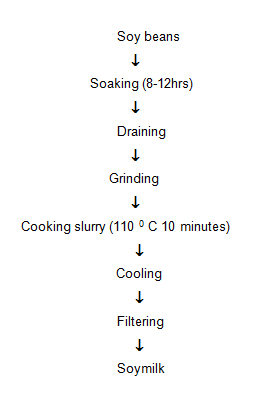

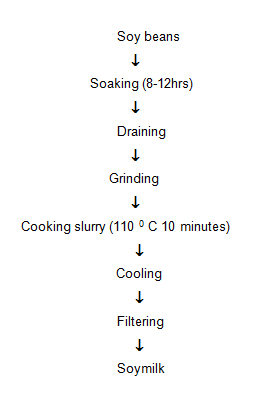

SOYABEAN MILK **

Processing of Soy milk

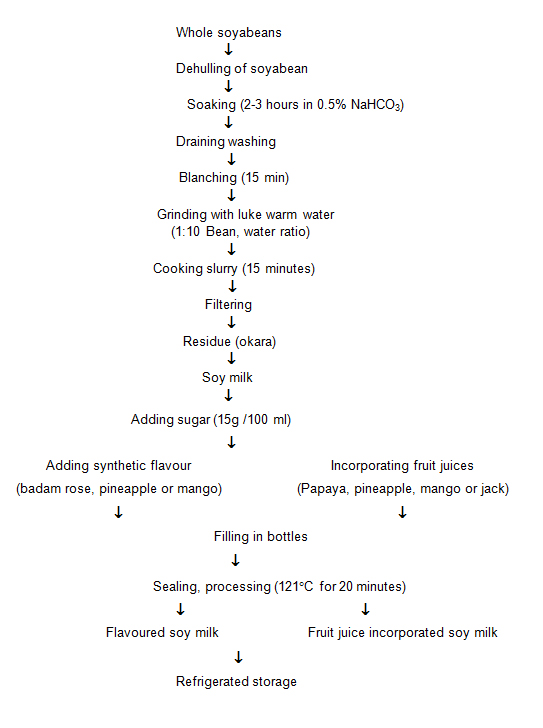

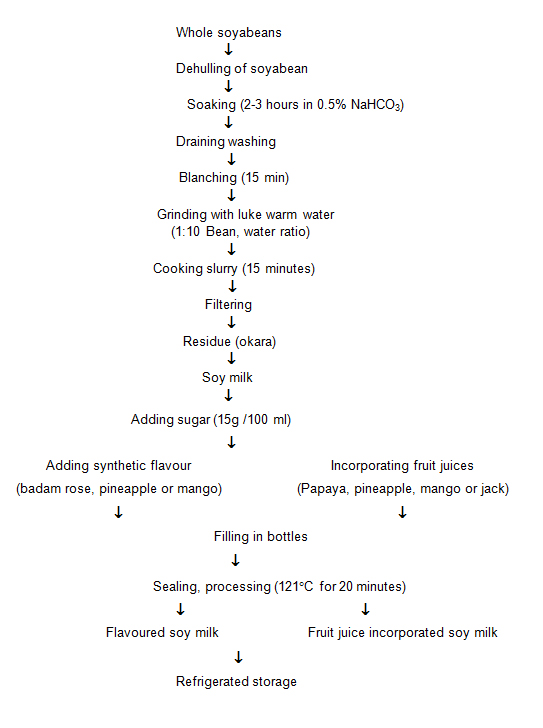

PROCESSING OF FRUIT INCORPORATED SOYMILK **

TOFU (SOY PANEER) **

-

Soyabean is soaked overnight in water, dehulled and ground to a fine paste with water (water to bean ratio of 10:1).

-

The milk is filtered, boiled and cooled.

-

A water suspension of powdered calcium sulphate is added (2.3kg/100 kg soyabean).

-

The proteins are precipitated as a thick curd.

-

The whey is drained of by transferring the materials to perforated aluminimum trays.

-

The curd is washed with water.

-

It is used in 2 to 3 days.

-

This can be used as a substitute for cottage cheese in cookery.

-

The quality of residue (Okara) obtained from dehulled soydhal is of superior quality compared to whole soyabean okara hence can be used for food applications.

-

To avoid setting up of the beany flavour even due to slight damage in dehulling it is advisable to dehull the soyabean just before the processing.

SOYA SAUCE **

Soya sauce is made by months of fermentation. Soya sauce is prepared in a variety of forms and is produced from a long and complex fermentation with various fungi and bacteria. Soyabeans are cooked for 4 or 6 hours and cooled. They are then mixed with an equal quantity of roasted ground wheat and the mixture, under suitable conditions, is seeded with Aspergillus oryzae. After the initial fermentation, salt is added and the product is matured for 6 months to 3 years when further fermentation occurs. When ripening is complete, the product is strained. Soya sauce thus obtained contains 67 percent moisture and 5 to 6 per cent protein.

OTHER PREPARATIONS FROM SOYABEAN

Tempeh is prepared by cooking and skinning soyabeans inoculated with a little tempeh from the previous batch. The mixture is mashed and wrapped in banana leaves and allowed to ferment for 24 hours. Tempeh is prepared by cooking and skinning soyabeans inoculated with a little tempeh from the previous batch. The mixture is mashed and wrapped in banana leaves and allowed to ferment for 24 hours.

Natto is a Japanese product. The soyabeans are soaked in water cooked and inoculated with Bacillus subtilis or previously prepared Natto. They are then wrapped in barks of pines and are allowed to ferment under vacuum conditions at 40 for 20 hours. for 20 hours.

Soyabeans can be sprouted, wet ground and added to cereal flour for the preparation of dosa, dhokla after fermentation. Soyabean meat food science is involved in the making foods that look and taste like meat but are made from soyabean proteins. If soyabean proteins are dissolved in alkali they form a sticky liquid. This liquid may be extracted through tiny holes and then recoagulated in an acid bath in the form of fibres. The fibres then can be spun into ropes with texture approaching the fibres texture of chicken or beef muscle tissue. The fabricated tissue then can be interlaced with fast-food flavorings and food colours. Products are almost indistinguishable from chicken meat, fish, hen or beef. This soyabean meat like products can be used by vegetarians and for patients with special dietary restrictions such as controlled levels of fat. Soyabeans can be sprouted, wet ground and added to cereal flour for the preparation of dosa, dhokla after fermentation. Soyabean meat food science is involved in the making foods that look and taste like meat but are made from soyabean proteins. If soyabean proteins are dissolved in alkali they form a sticky liquid. This liquid may be extracted through tiny holes and then recoagulated in an acid bath in the form of fibres. The fibres then can be spun into ropes with texture approaching the fibres texture of chicken or beef muscle tissue. The fabricated tissue then can be interlaced with fast-food flavorings and food colours. Products are almost indistinguishable from chicken meat, fish, hen or beef. This soyabean meat like products can be used by vegetarians and for patients with special dietary restrictions such as controlled levels of fat.

The following soy based products provide product variety for consumers. These are nutritious and have very good acceptability.

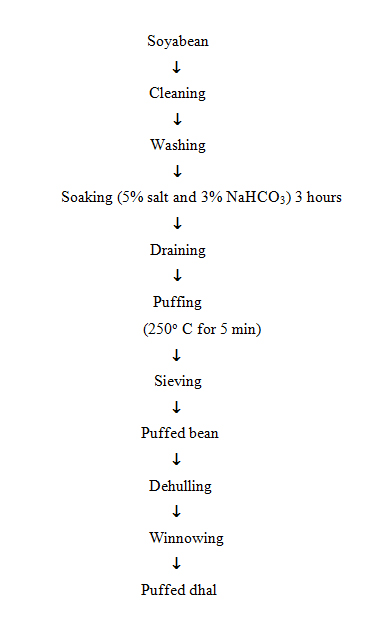

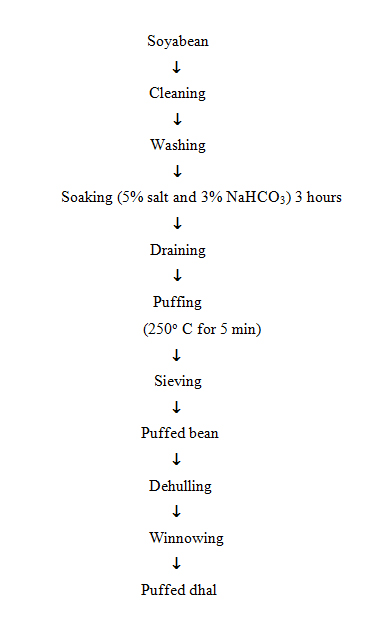

PUFFING OF SOYABEAN **

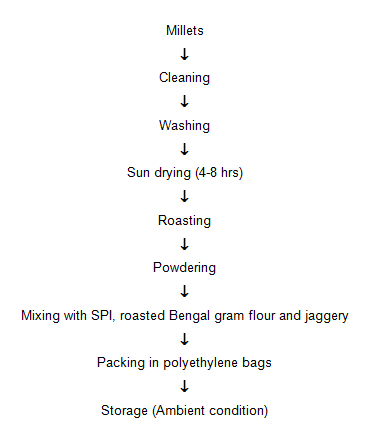

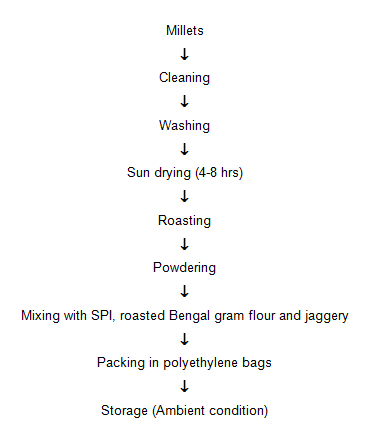

PREPARATION OF SOYA PROTEIN ISOLATE (SPI) INCORPORATED SUPPLEMENTARY FOOD **

PREPARATION OF KHAKARA **

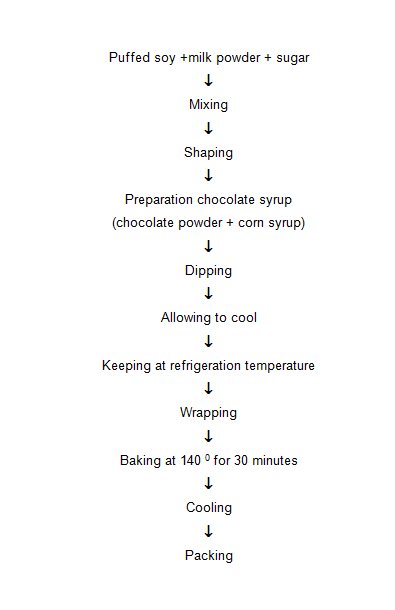

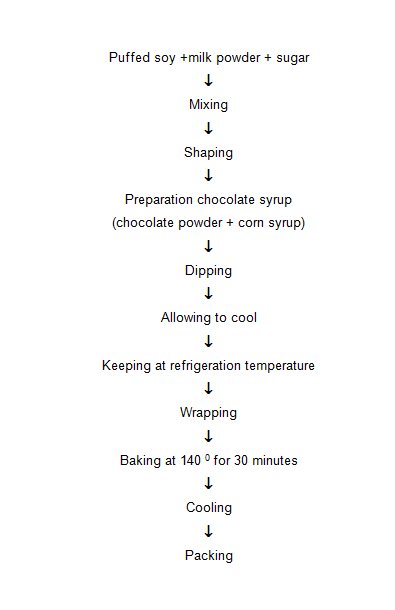

SOY CHOCOLATE **

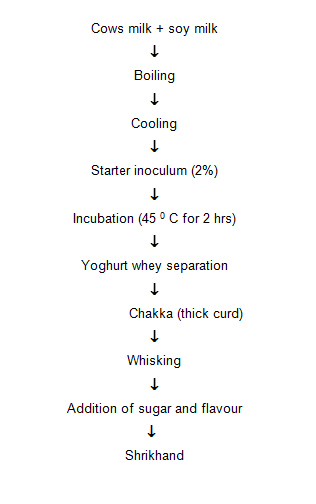

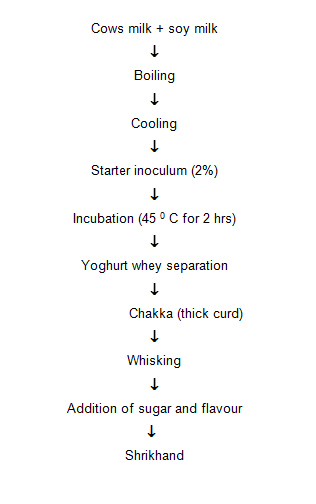

PREPARATION OF SHRIKHAND **

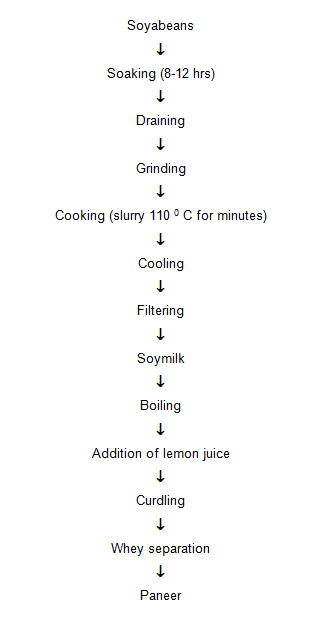

PROCESSING OF SOYMILK PANEER **

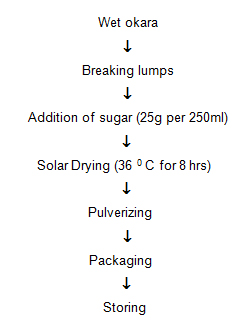

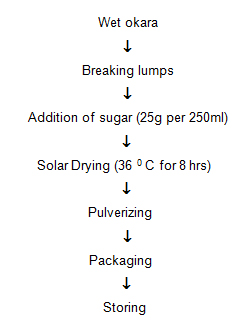

PREPARATION OF WET OKARA ** PREPARATION OF WET OKARA **

2. INSTANT FOOD MIX**

Top

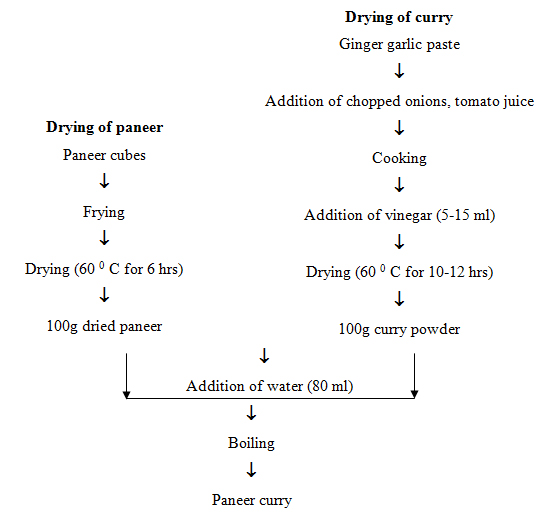

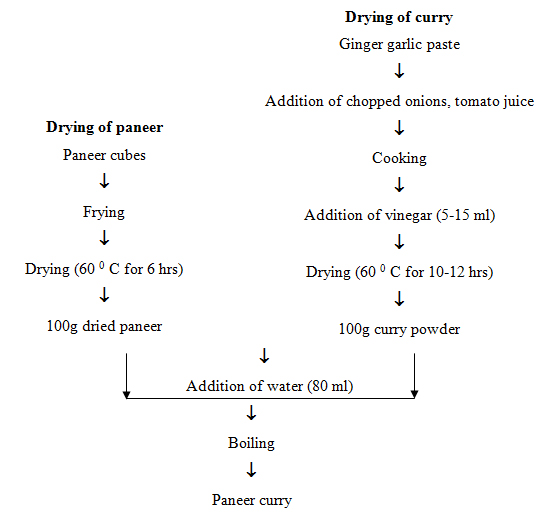

a. DEHYDRATED PANEER MIX **

b. PREPARATION OF PAKODA MIX *

Pakoda and murukku are the snack items prepared by using pulse and cereal combinations. They are deep fat fried foods.

Preparation of pakoda instant mix

Ingredients

Raw ingredients (g) |

|

Bengal gram flour |

100 |

Rice flour |

25 |

Salt |

3 |

Chilli powder |

1 |

Sodium bicarbonate |

0.1% |

Aniseed |

1 |

Dalda |

1 |

Method

All the ingredients were mixed thoroughly and sieved twice. |

Preparation of pakoda from instant mix

Other ingredients needed for preparing pakoda

Big onions |

2 nos. |

Green chillies |

2 nos. |

Chopped curry and coriander leaves |

2 g |

Oil |

200 ml |

Water |

80 ml / 100 g |

Method

-

A thick dough was prepared from instant pakoda mix by adding water.

-

Chopped onion, chopped curry leaves and coriander leaves were added to the batter and mixed well. The batter was kept for as such for 5 minutes.

-

Oil was taken in a frying pan and heated to 150  .The dough was fried in the heated oil till it turns golden brown in colour.

|

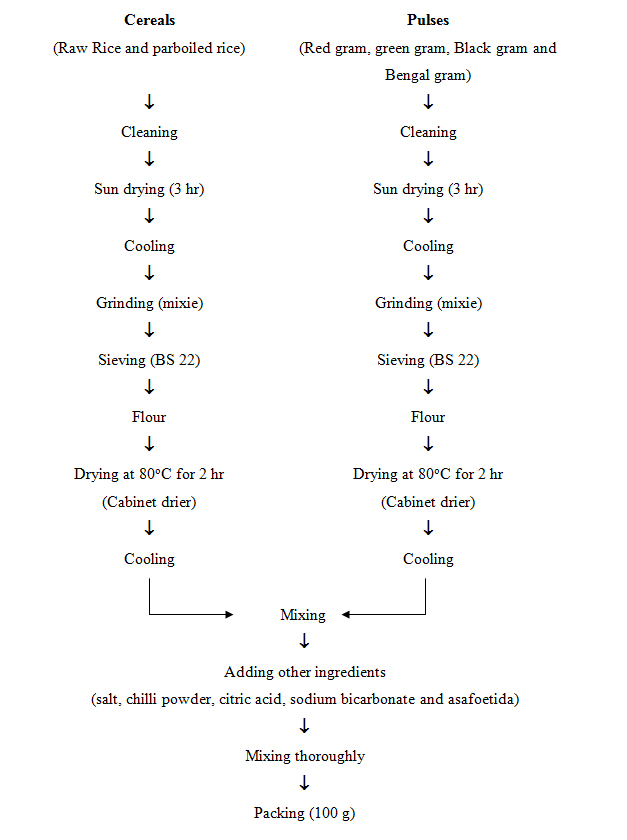

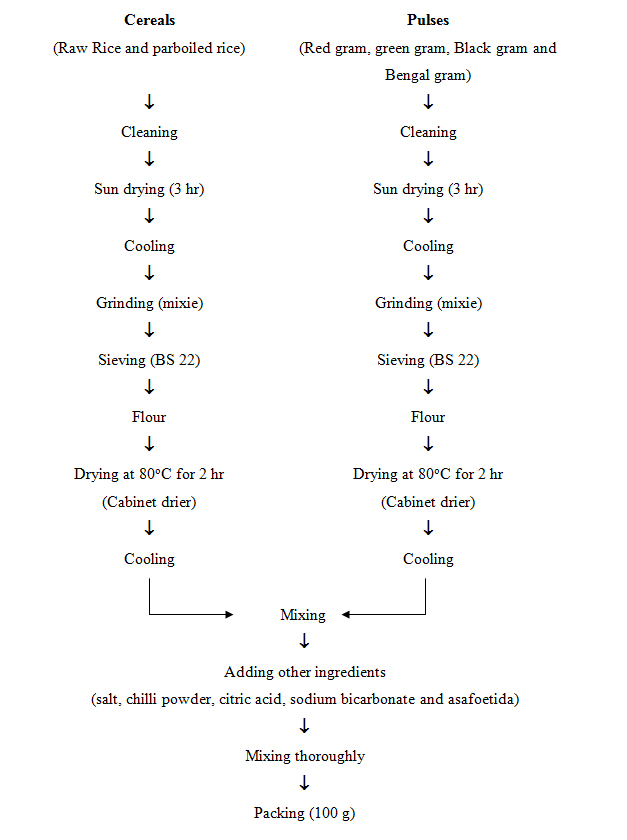

c. PREPARATION OF INSTANT ADAI MIX *

Adai is a traditional food for the South Indians. It is prepared from the combination of cereals and pulses. It is a unfermented food. Legumes provide the protein supplement to the diet which primarily consists of carbohydrates. The complementary nutritive value of cereals and pulses suggest that the most practical means of eradicating the widespread protein calorie malnutrition in several areas of the world is to increase the supply of cereal pulse mixtures for human diets.

Method

Preparation of the samples

Cleaning: The parboiled rice, raw rice, black gram dhal, red gram dhal, green gram dhal and bengal gram dhal were purchased from the local market, cleaned to remove immature, weeviled, broken and damaged grains, dried for two to three hours in sun, cooled and stored in the air tight containers till they were used.

Grinding of cereal and pulses : The cereals and pulses were ground in a mixie separately and sieved in BS 22 sieve. The ground flours were dried separately in a cabinet drier at 80 for two hr, cooled and used for instant adai mix preparation. for two hr, cooled and used for instant adai mix preparation.

Mixing of ingredients : The ground cereals and pulses were mixed in the following proportions

Raw ingredients used for instant adai mixes

Raw ingredients (g) |

|

Parboiled rice |

200 |

Raw rice |

200 |

Black gram |

200 |

Green gram |

200 |

Red gram |

200 |

Bengal gram |

200 |

Salt |

20 |

Chilli powder |

35 |

Asafoetida |

3.0 |

Citric acid |

1.0 |

Sodium bicarbonate |

1.0 |

Total (g) |

1260 |

Method

The weighed cereal and pulse flours were mixed by using ladle continuously in a round bottom vessel by adding small quantum at a time to get uniform mixing. Salt, citric acid, sodium bicarbonate, chilli powder and asafoetida were added to it and mixed thoroughly. |

Adai preparation

Batter preparation : To 100 g of instant adai mix, 200 ml of water was added and mixed well. The prepared batter was allowed to stand for 15 minutes at room temperature before preparing adai.

Other ingredients needed

Onion – 33 g, ginger – 1.3 g, garlic – 0.6 g, curry leaves – 3.3 g, oil – as required.

The onion, ginger, garlic and curry leaves were cut into pieces and mixed with batter.

Preparation of adai

The prepared batter was poured on the pre-heated tawa (Shallow fat frying pan) and spread uniformly with a ladder (thickness of 5 mm and diameter of 12 cm). The adai was cooked in the heated tawa by sprinkling oil on the surface for 2-3 ml. The prepared adai was light brown in colour. Adai batter can also be prepared either with water and curd or water and tomato juice in the ratio of 1:1. The prepared adai was organoleptically evaluated.

Flow chart for the preparation of instant adai mix

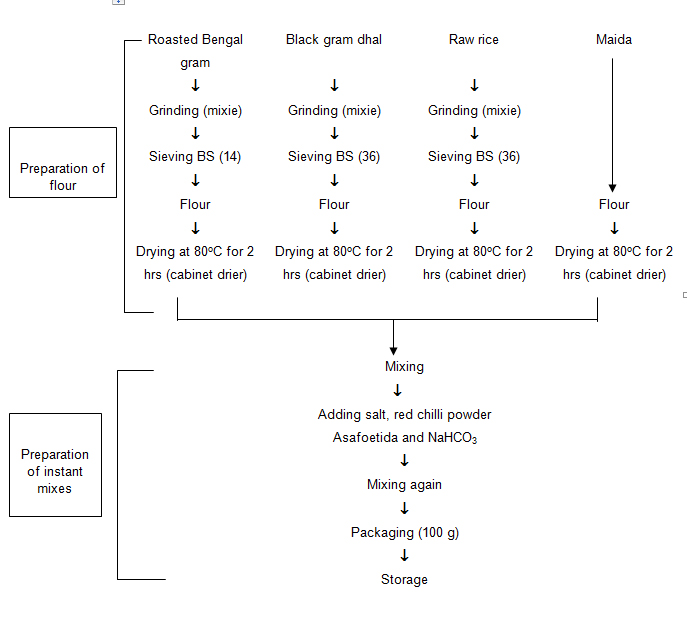

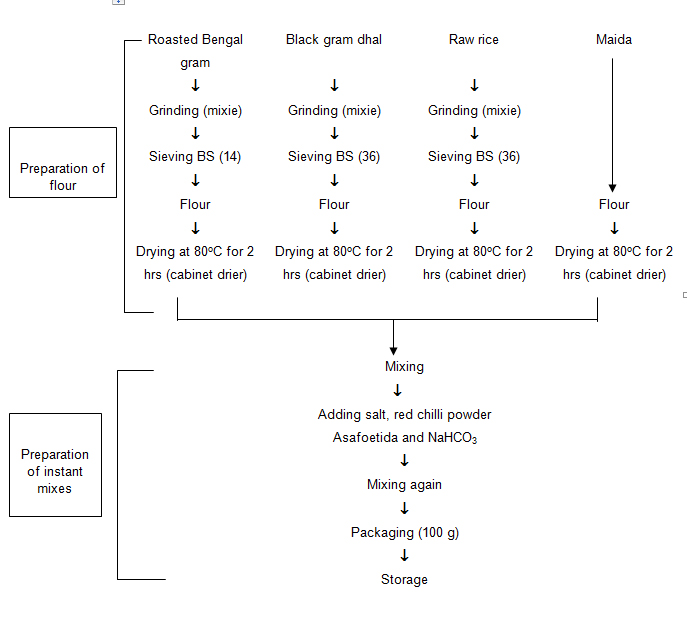

d. PREPARATION OF INSTANT VADA AND BAJJI MIXES

Vada and bajji are the unfermented traditional snack items for the South Indians. The instant vada and bajji mixes are generally made from flours of bengal gram, black gram, wheat and rice. Frying not only aids in cooking, it also contributed to destruction of anti-nutritive factors, moisture evaporation and thereby increase shelf stability.

Method

Preparation of instant vada mix *

Grinding pulses and raw rice

The bengal gram dhal, black gram dhal and raw rice were ground in a mixie separately. The ground bengal gram was sieved in a BS 14 sieve and the rest of the items were sieved in BS 36. Then the ground flours were dried separately in a cabinet drier at 80 for two hours, cooled and stored in an airtight containers till they were used. for two hours, cooled and stored in an airtight containers till they were used.

Preparation of instant vada mix

Ingredients

Bengal gram dhal flour |

85 g |

Black gram dhal flour |

5 g |

Raw rice flour |

5 g |

Maida |

2 g |

Salt |

2 g |

Hydrogenated fat (dalda) |

20 g |

Citric acid |

0.01 per cent |

Sodium bicarbonate |

0. 1 per cent |

Method

-

The ground bengal gram dhal was mixed with maida and the flours of black gram dhal and rice.

-

The salt, citric acid and sodium bicarbonate were added to it and mixed well.

-

Melted cooled hydrogenated fat was mixed with the instant vada mix.

-

Another batch of vada mix was prepared without adding hydrogenated fat.

|

Preparation of vada from instant vada mix *

Onion |

15 g |

Green chillies |

15 g |

Curry and coriander leaves |

2 g |

Aniseed |

2 g |

Ginger |

5 g |

Oil |

150 ml |

Water |

65 ml/100 g |

Method

-

The onion, green chilles, ginger, curry and coriander leaves were cut into pieces.

-

These were mixed with instant vada mix.

-

The dough was prepared by adding required quantity of water (65 ml/100g) and allowed to stand for 30 min.

-

The dough was made into a medium size balls and flattened into a round shape vada (dia 5.2 cm).

-

The oil (150 ml) was taken in a deep fat frying pan and heated to 150  .

-

The vada was fried in the heated oil for 5 min. until light brown in colour.

-

The required quantum of dalda was added to the instant vada mix packed without dalda while preparing vada.

|

Preparation of instant bajji mix

Ingredients

|

Proportions (g) |

Bengal gram flour |

80 |

Black gram flour |

5 |

Raw rice flour |

5 |

Maida flour |

10 |

Red chilli powder |

10 |

Salt |

3 |

Asafoetida |

1 |

Sodium bicarbonate |

0.1% |

| Method: All the ingredients were mixed thoroughly and sieved twice. |

Preparation of bajji from instant mix

Other ingredients needed for preparing bajji

Big onions : 50 g

Oil : 150 ml

Water : 120 ml / 100g

Method

e. KURUMA POWDER MIX *

Ingredients

Red gram dhal |

50 g |

Coriander |

125 g |

Cumin seeds |

8 g |

Cinnamon |

3 g |

Cloves |

1 g |

Pepper |

7.5 g |

Poppy seeds |

2.0 g |

Ani seeds |

2 g |

Turmeric |

5 g |

Red chillies |

2 g |

Asafoetida |

2 g |

f. PREPARATION OF IDLI PODI *

Ingredients

Red gram dhal – 75 g, black gram dhal – 25 g, dried chillies – 4 Nos, white sesame seed – 10 g, asafoetida powder – 3 g, curry leaves – 10 g, salt – 5.0 g, garlic powder – 5 g, refined groundnut oil – for frying.

Method

Fry red gram dhal and black gram dhal in oil till the flavour comes out. Fry dried chillies, white sesame seed and curry leaves separately. Powder all the ingredients separately and cool it. Mix all the powdered ingredients and pack it either polythene bags or air tight plastic containers.

g. PREPARATION OF PARUPPUPODI *

Ingredients

Red gram dhal – 500 g, bengal gram – 400 g, dried chillies – 15 nos, black gram dhal – 50 g, cumin – 10 g, pepper – 10 g, curry leaves – 10 g, asafoetida – 5 g, salt – 150 g.

Method

Fry all the ingredients separately and made into powder by using machine (Huller). Mix all the ingredients, sieve it and pack it either polythene bags or air tight plastic containers.

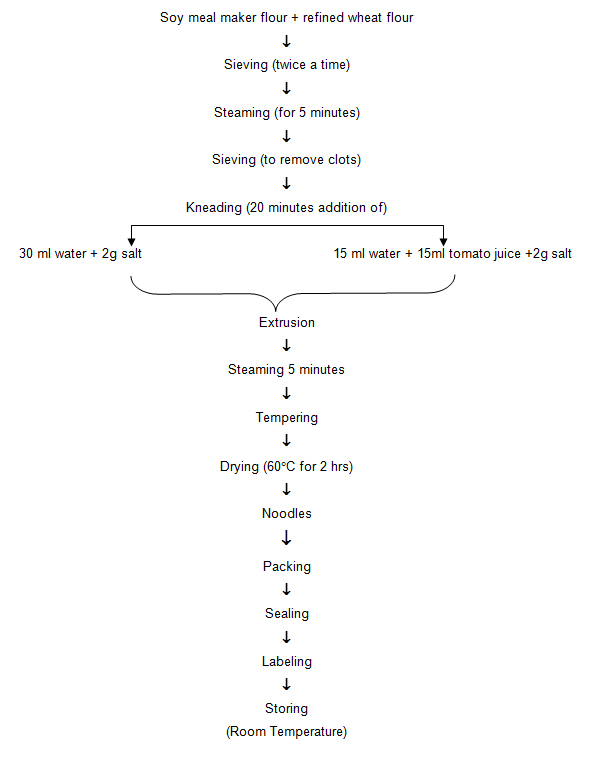

3. PREPARATION OF EXTRUDED PRODUCTS

Top

Extrusion is one of the most versatile operations available to the food industry for transforming ingredients into intermediate or finished products. Extrusion has been used to produce a wide variety of foods such as snack, ready-to-eat cereals, textured vegetable protein, confectioneries and pet foods.

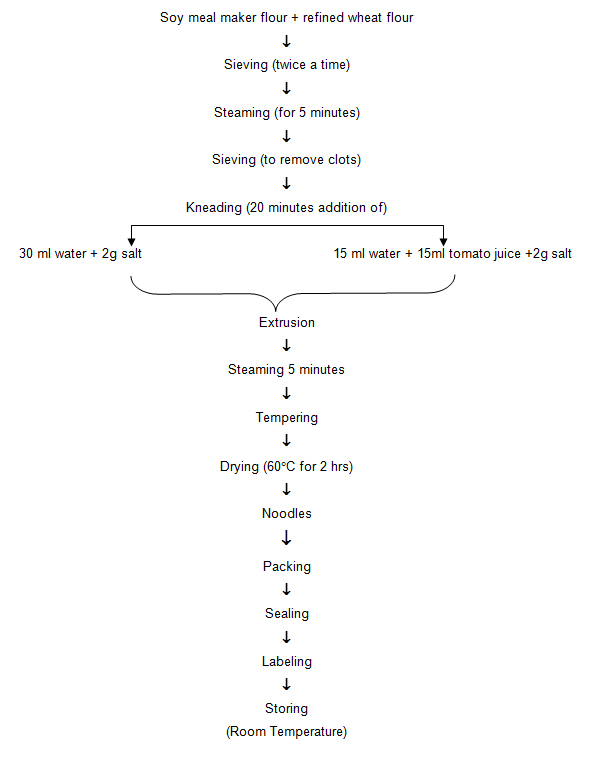

a. FLOW CHART FOR THE PREPARATION OF NOODLES **

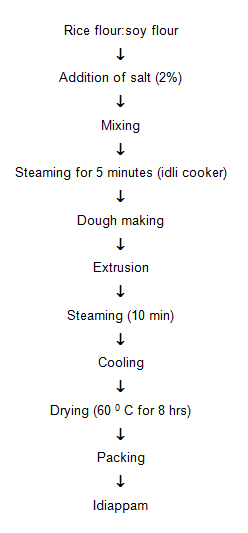

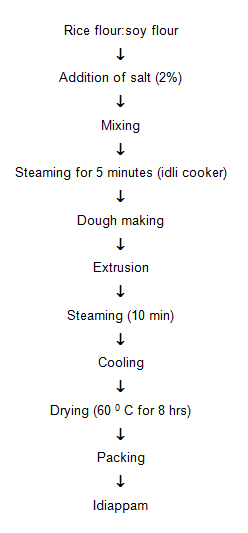

b. PREPARATION OF IDIAPPAM **

4. BAKERY PRODUCTS

Top

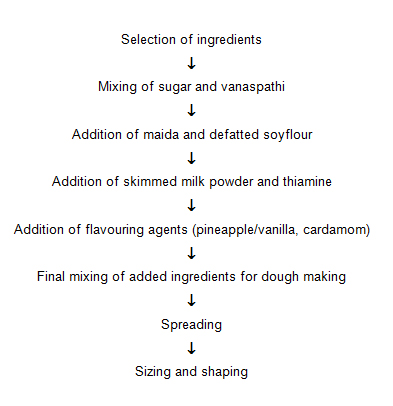

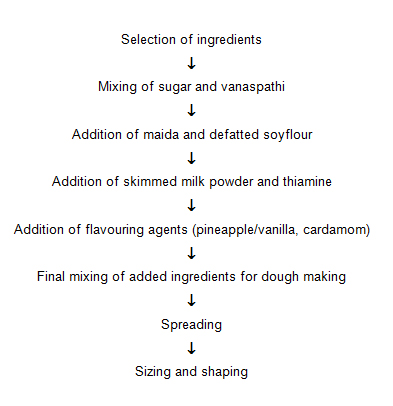

SOY BISCUIT **

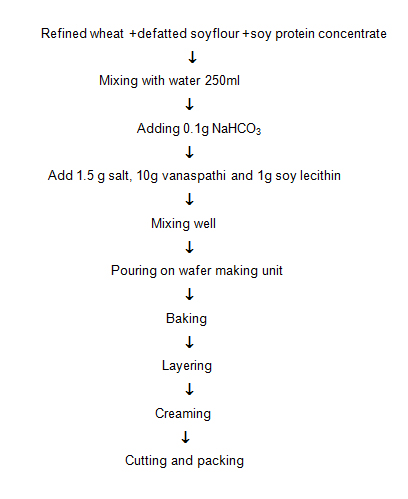

SOY WAFERS **

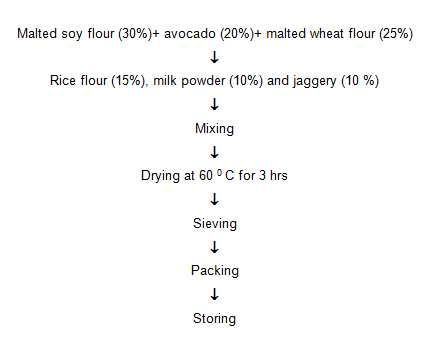

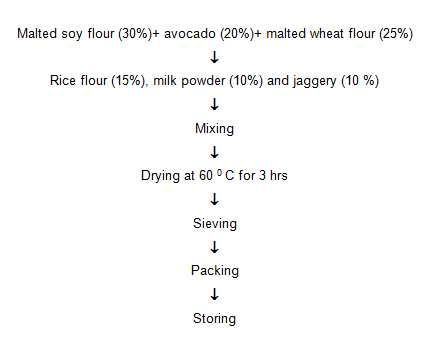

SOY AVOCADO WEANING FOOD **

Technologies Available

* - Post Harvest Technology Centre, TNAU, Coimbatore.

** - Home Science College and Research Institute, TNAU, Madurai.

Source

http://outofthegarden.files.wordpress.com/2006/08/papad.JPG

http://d1.biggestmenu.com/00/00/4a/52917e42296dfb5d_m.jpg

tvp : asiarecipe.com/soyproducts.html

http://z.about.com/d/japanesefood/1/0/v/J/soymilkjuiceblog.jpg

http://www.justhungry.com/images/okara.jpg

http://www.randa.ru/pic/prod/banan_b.jpg

USDA Nutrient database |

Tempeh is prepared by cooking and skinning soyabeans inoculated with a little tempeh from the previous batch. The mixture is mashed and wrapped in banana leaves and allowed to ferment for 24 hours.

Tempeh is prepared by cooking and skinning soyabeans inoculated with a little tempeh from the previous batch. The mixture is mashed and wrapped in banana leaves and allowed to ferment for 24 hours. Soyabeans can be sprouted, wet ground and added to cereal flour for the preparation of dosa, dhokla after fermentation. Soyabean meat food science is involved in the making foods that look and taste like meat but are made from soyabean proteins. If soyabean proteins are dissolved in alkali they form a sticky liquid. This liquid may be extracted through tiny holes and then recoagulated in an acid bath in the form of fibres. The fibres then can be spun into ropes with texture approaching the fibres texture of chicken or beef muscle tissue. The fabricated tissue then can be interlaced with fast-food flavorings and food colours. Products are almost indistinguishable from chicken meat, fish, hen or beef. This soyabean meat like products can be used by vegetarians and for patients with special dietary restrictions such as controlled levels of fat.

Soyabeans can be sprouted, wet ground and added to cereal flour for the preparation of dosa, dhokla after fermentation. Soyabean meat food science is involved in the making foods that look and taste like meat but are made from soyabean proteins. If soyabean proteins are dissolved in alkali they form a sticky liquid. This liquid may be extracted through tiny holes and then recoagulated in an acid bath in the form of fibres. The fibres then can be spun into ropes with texture approaching the fibres texture of chicken or beef muscle tissue. The fabricated tissue then can be interlaced with fast-food flavorings and food colours. Products are almost indistinguishable from chicken meat, fish, hen or beef. This soyabean meat like products can be used by vegetarians and for patients with special dietary restrictions such as controlled levels of fat.

PREPARATION OF WET OKARA **

PREPARATION OF WET OKARA **