PROCESSING EQUIPMENTS

Processing involved three steps

Step 1

Pre- conditioning and pre cleaning

Pre conditioning: Isolation of seed from plant parts with which it was harvested e.g. Shelling

Pre cleaning

Removal of external materials like trash, stones, clods which are either in larger size or lighter in weight. No pre cleaning is required for hand harvested and winnowed seeds

The machineries involved in this operation are,

Scalper

It removes the larger inert matter from the seeds. If it contains a single sieve it is called as scalpers, two sieves – rough cleaners. The unit consists of a vibrating or rotating screen or sieve having perforation large enough to allow the rough seed pass through readily.

Seed Scalper

Debearders

The machine has horizontal beater with arms rotating inside a steel drum. When the seeds pass through it do the action of rubbing the seeds and clip the seeds of oats, debeard barley, thresh white cap in wheat, remove awns and beards, de hull some grass seeds and polish the seed.

Debearders

Huller – scarifier

Have two rubber faced rough surfaces to rub the seeds. Dehulling (removal of outer coat or husk) and scarifier (scratching the seed coat) can be done simultaneously or separately. Its operations,

Seed – rotating disc- centrifugal force – thrown – huller- - suction chamber- removes lighter seeds .

Maize sheller

1. High capacity power operated shellers - bulk

2. Hand shellers – breeder or nucleus seed.

Step 2

Cleaning

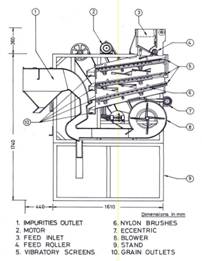

The second stage of cleaning is carried out with air blasts and vibrating screens and is applicable to all kinds of seeds. It is essentially the same as scalping but more refined. It is performed mostly by one machine known as air-screen cleaner.

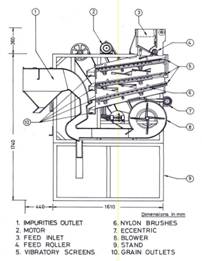

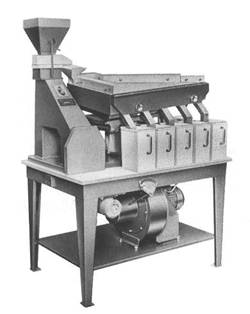

Air-Screen cleaner cum grader

The air-screen machine is the basic cleaner in most seed processing plants. Almost all seed must be cleaned by air-screen cleaner before specific specifications can be attempted. Machine size varies from small, two-screen farm models to large industrial cleaners with 7-8 screens. Two-screen models are used on farms, in breeder and foundation seed programs and by experiment stations for processing small quantities of seed. In most machines separations are made on the basis of differences in only one physical characteristic.

The air-screen machine, however, effects separations on the basis of differences in size and weight of seeds. This enables the air-screen machine to use three cleaning elements: aspirator, in which light material is removed from the seed mass; scalper in which good seed are dropped through screen openings; but larger material is carried over the screen into a separate spout; and grader, in which good crop seed ride over screen openings, while smaller particles drop through.

Step 3

Cleaning and Grading

To obtain quality seed, it is necessary to clean the seed obtained from the farm to get rid of inert materials, weed seeds, other crop seeds, other variety seeds, damaged and deteriorated seed. Different kinds of seeds can be separated when they differ in one or more physical characteristics. Physical characteristics normally used to separate seeds are size, shape, length, weight, colour, surface texture, affinity to liquids, electrical conductivity, etc. The problem lies in identifying the most important property and use the machine that separates seed using the identified property. Some of the identified properties and machines operating by following the properties are listed below:

| Name of the Separator |

Property followed |

Uses |

| Vibratory separator |

Shape and surface texture |

Removal of weed seeds |

| Spiral separator |

Shape or the degree of its ability to roll |

Separation of damaged/flat and wrinkled seeds from smooth seeds. Separation of mustard, rape, soybean and peas from wheat, flax, oats, etc., and round seeds from flat seeds. |

| Disk / Indented cylinder separator |

Length |

Dissimilar material like wheat, rye, mustard, barley from oats |

| Electrostatic separator |

Electrical property |

Johnson grass from sesame seed |

| Electronic colour sorters |

Colour / brightness |

Separation of off coloured seeds |

| Inclined draper |

Shape and surface texture |

Separation of smooth or round seeds from rough flat or elongated seeds |

| Magnetic separator |

Surface texture and stickiness |

Removal of contaminating weed seed from clovers, alfalfa seeds and iron metals |

| Roll mill |

Shape and surface texture |

Separation of smooth clover seed |

| Gravity separator or Destoner |

Density or specific gravity |

Removal of badly damaged, deteriorated, insect damaged crop seed and stones from good seeds. |

Upgrading

Seed lots require further cleaning treatment to remove adulterants that are similar to pure seed in size and shape, to be separated by air screen cleaner. Removal of seeds larger or smaller than required size (sizing) and removal of cracked, damaged or otherwise defective seeds (grading) is accomplished in this final stage of processing.

Specific gravity separation

This method makes use of a combination of weight and surface characteristics of the seed to be separated. The principle of floatation is employed here. A mixture of seeds is fed onto the lower end of a sloping perforated table. Air is forced up through the porous deck surface and the bed of seeds by a fan, which stratifies the seeds in layers according to density with the lightest seeds and particles of inert matter at the top and the heaviest at the bottom. An oscillating movement of the table causes the seeds to move at different rates across the deck. The lightest seeds float down under gravity and are discharged at the lower end, while the heaviest ones are kicked up the slope by contact with the oscillating deck and are discharged at the upper end. This machine separates seeds of the same density but of different size and seeds of the same size but of different densities.

Specific gravity separator

Indented cylinder

This helps to separate seeds according to the length. The equipment consists of a slightly inclined horizontal rotating cylinder and a movable separating trough. The inside surface has small closely spaced hemispherical indentations. Small seeds are pressed into the indents by centrifugal force and can be removed. The larger seeds flows in the centre of the cylinder and is discharged by gravity.

Magnetic separator

The magnetic separator separates seed according to its surface texture or related seed characteristics. First, seed is treated with iron filings, which adhere to rough surface alone. The treated seed lot is passed over a revolving magnetic drum and separated from smooth, uncoated seed. It may help to add varied amounts of water while mixing seed and powder, depending on the seed type. At any rate, the effectiveness of magnetic separation depends on the components of the seed lot and on the powder and water used in the treating operation. The greater the difference between surface textures of the seed lot’s components, more effective will be the separation.

Principle of function

|

Colour separator

The colour separator is used to separate discoloured seed, greatly of lower quality. Separation based on colour is necessary because the density and dimensions of discoloured seed are the same as those of sound seed, so other machines are not effective for separation. Electronic colour separation uses photocells to compare the seed colour with “background” which are selected to reflect the same light as the good seed. Seed that differs in colour is detected by the photo cells, which generate an electric impulse. The impulse activates an air jet to blow away the discoloured seed.

Separating Seed by Color

The color sorter (right) uses an electronic eye that can pick up different colors according to the way the machine is adjusted. As seed falls down a shoot, it passes through the electric eye. If the color of the seed is different than the desired color, the electric eye will activate a sudden burst of air that pushes that seed into a reject bin while the rest of the seed passes through to another bin.

Friction cleaning

The air-screen combinations cannot remove debris that has a size and density similar to the seeds. However, if the debris has a different surface texture, it may be possible to remove by friction cleaning. Any object rolling or sliding over a sloping surface encounters a certain friction depending on the texture of itself and that of the sloping surface. Separation is made on a velvet cloth or rubber belt with variable inclination, which ensures that the slope necessary for the run off of the seed is different from the slope necessary for run -off of the debris. The belt continuously moves upwards and removes the debris while the seeds roll down the slope.

Spiral separator

The separator, which classifies seed according to its shape and rolling ability, consists of sheet metal strips fitted around a central axis in the form of a spiral. The unit resembles an open screw conveyor standing in a vertical position. The seed is introduced at the top of the inner spiral. Round seeds roll faster down the incline than flat or irregularly shaped seeds, which tend to slide or tumble. The orbit of round seed increases with speed on its flight around the axis, until it rolls over the edge of the inner flight into the outer flight where it is collected separately. The slower moving seed does not build up enough speed to escape form the inner flight. Most spirals have multiple inner flights arranged one above the other to increase the capacity.

Liquid flotation

Cleaning by flotation relies on the principle that the density of the seed of a given species is specific both for filled and ill filled seed. In this method, liquids with a density or specific gravity between that of the full and empty seed are used. The specific gravity of the liquids used is such that the full seed sinks and the empty seed and light debris float.

Top |