|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Components |

| Home | Nutrient Management | Weed Management | Pest Management | Disease Management | Gallery | Contact |

|

Special Technologies |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ORGANIC FARMING :: Composting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Organic Farming - Introduction |

Biodynamic Farming |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Composting 4. Value addition of Poultry Waste through Composting Technology Composting is the natural process of 'rotting' or decomposition of organic matter by microorganisms under controlled conditions. Raw organic materials such as crop residues, animal wastes, food garbage, some municipal wastes and suitable industrial wastes, enhance their suitability for application to the soil as a fertilizing resource, after having undergone composting. Compost is a rich source of organic matter. Soil organic matter plays an important role in sustaining soil fertility, and hence in sustainable agricultural production. In addition to being a source of plant nutrient, it improves the physico-chemical and biological properties of the soil. As a result of these improvements, the soil: (i) becomes more resistant to stresses such as drought, diseases and toxicity; These advantages manifest themselves in reduced cropping risks, higher yields and lower outlays on inorganic fertilizers for farmers. Dung and urine produced by animals per day

Nutritive value of animal solid and liquid excreta

Why composting is necessary?

Advantages of Composting

Drawbacks of Using Composts

Composting organic materials with high lignin content - lime treatment

Composting weeds

Materials Required

Compost enrichmentFarm compost is poor in P content (0.4-0.8 percent). Addition of P makes the compost more balanced, and supplies nutrient to micro-organisms for their multiplication and faster decomposition. The addition of P also reduces N losses. Compost can be enriched by:

The Benefits of Using Composts to Agriculture Compost has been considered as a valuable soil amendment for centuries. Most people are aware that using composts is an effective way to increase healthy plant production, help save money, reduce the use of chemical fertilizers, and conserve natural resources. Compost provides a stable organic matter that improves the physical, chemical, and biological properties of soils, thereby enhancing soil quality and crop production. When correctly applied, compost has the following beneficial effects on soil properties, thus creating suitable conditions for root development and consequently promoting higher yield and higher quality of crops. Improves the Physical Properties of Soils

Enhances the Chemical Properties of Soils

Improves the Biological Properties of Soils

Economic and Social Benefits of Composting The economic and social benefits of composting include the following:

Crop residues are the non-economic plant parts that are left in the field after harvest. The harvest refuses include straws, stubble, stover and haulms of different crops. Crop remains are also from thrashing sheds or that are discarded during crop processing. This includes process wastes like groundnut shell, oil cakes, rice husks and cobs of maize, sorghum and cumbu. The greatest potential as a biomass resource appears to be from the field residues of sorghum, maize, soybean, cotton, sugarcane etc. In Tamil Nadu 190lakh tones of crop residues are available for use. These residues will contribute 1.0 lakh ton of nitrogen, 0.5 lakh ton of phosphorusand2.0 lakh tons of potassium. How ever crop residues need composting before being used as manure. Waste collection Crop residues accumulated in different locations are to be brought to compost yard. The compost yard is located in anyone corner of the farm with accessibility via good road. Water resource should also be available in sufficient quantity. The crop residues that are brought to compost yard should be heaped in one corner for further processing. Shredding of waste materials Particle size is one of the factors that influence the composting. It is advisable to shred all the crop residues that are used for composting. Shredding the waste manually is labour intensive. Shredder machine can be employed to shred all the crop residue biomass. Particle size of 2 to 2.5 cm is recommended for quick composting. Mixing of green waste and brown waste Carbon and nitrogen ratio decides the initiation of composting process. If C:N ratio is wide (100:1) composting will not take place. Narrow C:N ratio of 30:1 is ideal for composting. To get a narrow C:N ratio, carbon and nitrogen rich material should be mixed together. Green coloured waste materials like glyricidia leaves, parthenium, freshly harvested weeds; sesbania leaves are rich in nitrogen, whereas brown coloured waste material like straw, coir dust, dried leaves and dried grasses are rich in carbon. In any composting process these carbon and nitrogen rich material is to be mixed together to make the composting quicker rather than putting green waste alone or brown color waste alone for composting. Animal dung is also a good source of nitrogen. While making heap formation, alternative layers of carbon rich material, animal dung and nitrogen rich material are to be heaped to get a quicker result in composting. Compost heap formation Minimum 4 feet height should be maintained for composting. The composting area should be elevated one and have sufficient shade. While heap formation, all the crop residues should be mixed together to form a heterogeneous material rather than a single homogenous material. Alternate layers of carbon and nitrogen rich material with intermittent layers of animal dung are essential. After heap formation the material should be thoroughly moistened. Bioinputs for composting TNAU Biomineralizer consortium contains groups of microorganisms, which accelerate the composting process. If this inoculum is not added to the composting material, natural microorganisms establish on the waste material on its own and do the composting work. This process takes longtime. But if external source of inoculums is added, the microbial activity starts earlier and composting period will be reduced. For one ton of crop wastes 2 kg of TNAU Biomineralizer is recommended. This two kg Biomineralizer should be mixed with 20 liters of water and made slurry. When the compost heap is formed in between layers the slurry should be inoculated, so that it mixes with the waste material thoroughly for uniform coating of microorganism on the waste material. Cow dung slurry is also a good source for microbial inoculum. But it carries unwanted microorganisms also which may compete with composting organism. But when TNAU Biomineralizer is not available, cow dung slurry is a good source material. For one ton crop residues40 kg fresh cow dung is required. This 40 kg fresh cow dung is mixed with 100litres of water and it should be thoroughly poured over the waste material. Cow dung slurry acts as nitrogen source as well as source of microbial inoculum.

Aerating the compost material Sufficient quantity of oxygen should be available inside the compost heap. For this external air should be freely get in and comes out of the material. Normally to allow the fresh air to get inside, the compost heap should be turned upside down, once in fifteen days. In this process top layer comes to bottom and bottom layer goes to top. This process also activates the microbial process and compost process is hastened. In some cases air ventilating pipe maybe inserted vertically and horizontally, to allow the air to pass through. The wood chip that is available as waste in wood processing industry may also be used as bulking agent in the composting process. This bulking agent gives more air space to the compost material. Moisture maintenance Throughout the composting period 60% moisture should be maintained. On any situation, compost material should not be allowed to dry. If the material becomes dry, all the microorganisms present in the crop residues will die and the compost process gets affected. Compost maturity Volume reduction, black colour, earthy odor, reduction in particle size are all the physical factors to be observed for compost maturity. After satisfying with the compost maturity index, the compost heap can be disturbed and spread on the floor for curing. After curing for one day, the composted material is sieved through 4 mm sieve to get uniform composted material. The residues collected after composting has to be again composted to finish the composting process. Compost enrichment The harvested compost should be heaped in a shade, preferably on a hard floor. The beneficial microorganisms like Azotobacter or Azospirillum, Pseudomonas, Phosphobacteria (0.2%) and rock phosphate (2%) have to be inoculated for one ton of compost. Forty per cent moisture should be maintained for the maximum growth of inoculated microorganism. This incubation should be allowed for 20 days for the organism to reach the maximum population. Now the compost is called as enriched compost. The advantage of enriched compost over normal compost is the quality manure with higher nutrient status with high number of beneficial microorganisms and plant growth promoting substances. Nutritive value of Biocompost The nutritive value of Biocompost varies from lot to lot because of varying input materials. But in general Biocompost contains all the macro and micro nutrients required for crops, which is given in the following table. Even though the quantity available is low it covers all the requirements of the crop. Nutrient content of biocompost prepared from different crop residues

The common manurial value of different biocompost prepared from different substrate is given below. Benefits of Biocompost

Compost application Organic manures are highly regarded as good source of material to maintain soil health and increasing soil organic carbon content. Organic manures cannot be equated with inorganic fertilizers. But organic manures deliver all the nutrients to the soil but with little quantity. For one hectare of land 5 tons of enriched biocompost is recommended. It can be used as basal application in the field before taking up planting work. Limitation in Biocompost application

Sugarcane produces about 10 to 12 tonnes of dry leaves per hectare per crop. The detrashing is done on 5th and 7thmonth during its growth period. This trash contains 28.6%-organic carbon, 0.35 to 0.42% nitrogen, 0.04 to 0.15% phosphorus, 0.50 to 0.42% potassium. The sugarcane trash incorporation in the soil influences physical, chemical and biological properties of the soil. There is a reduction in soil EC, improvement in the water holding capacity, better soil aggregation and thereby improves porosity in the soil. Sugarcane trash incorporation reduces the bulk density of the soil and there is an increase in infiltration rate and decrease in penetration resistance. The direct incorporation of chopped trash increases the availability of nutrients leading to soil fertility. Sugarcane trash can be easily composted by using the fungi like Trichurus, Aspergillus, Penicillium and Trichoderma. Addition of rock phosphate and gypsum facilitates for quicker decomposition. Sugarcane trash composting Collection of trash The detrashed material has to be pooled together and transported to the compost yard. If no compost yard is available to farmer, anyone of the corner area in the sugarcane field itself can be used for making composting. There is no necessity to make a pit for composting. Composting can be done above the soil. Sugarcane trash is lengthy one. Handling and heaping the trash will be more cumbersome. It is recommended to shred the waste into small particles. This process reduces the volume of material, increases the surface area of the waste. If the waste material contains more surface area, more microorganisms work effectively on the surface and degradation will be faster. Shredder is the ideal instrument to shred all the sugarcane trash. Chop cutter machine can also be used for this purpose. If no machinery is available manual shredding is recommended. Without shredding the composting process will take long time. Inputs for composting (a) Microbial consortium TNAU biomineralizer is the consortium of microorganism recommended for composting all the agro wastes. For one ton of trash, two kg inoculums are recommended. Without the inoculation of microbial consortium, the composting process will take its own time. The alterative source required microorganism for composting is cow dung slurry. But in the cow dung slurry the required population of microorganism for composting is low and they have to compete with other microorganisms present in the cow dung for survival. In TNAU biomineralizer, only the required microorganism meant for composting alone is present with high population. Therefore it is recommended to go for TNAU biomineralizer. (b) Animal dung Animal dung or fresh poultry litter can be used as a source of nitrogen to reduce the C:N ratio. For one ton of sugarcane trash 50 kg fresh dung is recommended. The dung can be mixed with 100 litres of water and thoroughly mixed with sugarcane trash. Rock phosphate at 5 kg I ton waste can be added to increase the phosphorus content of the compost. Making heap formation After mixing all the inputs with sugarcane trash, heap should be formed with a minimum height of 4 feet. This height is required to generate more heat in the composting process, and the generated heat will be retained long time inside the material. Turning the compost material The compost material should be turned periodically once in 15daysto allow more aeration inside the material. In the turning process, bottom layer comes to top and top layer comes to bottom. So that uniform composting will occur. Moisture control Throughout the composting period 60% moisture should be maintained. If composting material is allowed to dry, all the established microorganisms get killed and composting process will be terminated. Moisture maintenance is the critical factor for good composting. Compost maturity Volume reduction, earthy odor, brownish black colour and reduction in particle size are important parameters to be observed for assessing compost maturity. Once the compost attained the maturity, the compost heap should be disturbed and spread the material for curing. After 24 hrs the composted material can be sieved through 4 mm sieve to get uniform compost material. The residues available after sieving will be recycled to the next composting batch for further composting. Nutritive value of sugarcane trash compost Sugarcane trash compost contains 0.5% nitrogen, 0.2% phosphorus and 1.1% potassium, in addition to micronutrients traces. Sugarcane trash compost is a good source of nutrients for sugarcane crop. Compost application The enriched compost can be applied at the rate of 5 tons per hectare, as basal application to the field. Whatever the compost derived from sugarcane trash, it can be ploughed back into sugarcane field to enrich the soil. Limitations in compost making and usage

4. Value addition of Poultry Waste through Composting technology Poultry industry is one of the largest and fastest growing livestock production systems in the world. In India, there are about 3430 million populations of poultry with a waste generation of 3.30 million tonnes per year. The localized nature of poultry production also means that it can represent a large percentage of the agricultural economy in many states or regions. Although economical and successful, the poultry industry is currently facing with a number of highly complex and challenging environmental problems, many of which are related to its size and geographically concentrated nature. From an agricultural perspective, poultry wastes playa major role in the contamination of ground water through nitrate nitrogen. Also, the eutrophication of surface water due to phosphorus, pesticides, heavy metals and pathogens present in the poultry wastes applied to soils are the central environmental issues at the present time. Among the animal manures, poultry droppings have higher nutrient contents. It has nitrogen (4.55 to 5.46 %), phosphorus (2.46 to 2.82 %), potassium (2.02 to 2.32 %), calcium (4.52 to 8.15 %), magnesium (0.52 to 0.73 %) and appreciable quantities of micronutrients like Cu, Zn, Fe, Mn etc. In addition to this cellulose (2.26 to 3.62%), hermicellulose (1.89 to 2.77 %) and lignin (1.07 to 2.16 %) are also present in poultry waste. These components upon microbial action can be converted to value added compost with high nutrient status. In poultry droppings, nearly 60%of nitrogen which is present as uric acid and urea is lost through ammonia volatilization by hydrolysis. This loss of nitrogen reduces the agronomic value of the product, besides causing atmospheric pollution. Composting with amendment seems promising in conservation of nitrogen in poultry droppings. Nitrogen in poultry waste can be effectively conserved by composting with suitable organic amendment. The technologies developed will be highly useful to the poultry farmers. Technology for composting of poultry wastes 1. Preparation of poultry waste compost using paddy straw Inputs required

A known quantity of fresh poultry droppings is to be collected and mixed thoroughly with chopped paddy straw (< 2 cm size) @ 1:1.25 ratio so as to attain a C/Nratio of 25 to 30 which is considered to be optimum for composting. Pleurotus sajor-caju is inoculated @ 5 packets (250 g each) per tonne of substrate. The poultry waste and paddy straw mix should be heaped under shade. The moisture content of the heap should be maintained at 50 to 60%. Periodical watering should be done once in 15 days and turning should be given on 21st, 35th and 42ndday of composting (avoid turning during first 3 weeks of composting). Within a period of 50 days, materials are converted to matured compost with the following nutrient contents;

II. Preparation of poultry waste compost using coir pith Inputs required

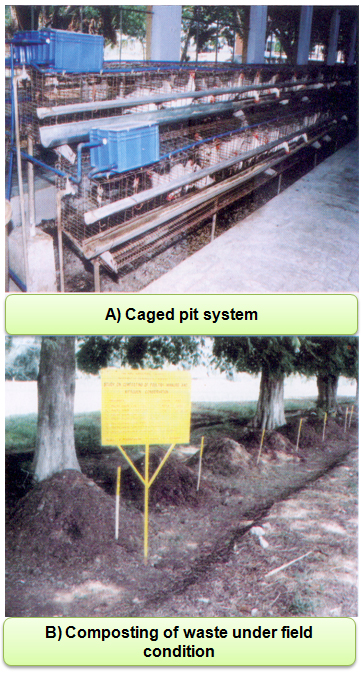

a. Collection of poultry waste from caged system A layer of 5 cm sea sand and 10cm coir pith should be spread in the manure collection pit of caged system where the poultry droppings are allowed to settle. Dry coir pith should be applied periodically as per the table given below. After a period of three months, the partially degraded coir pith and poultry droppings mix can be transferred to compost yard and heaped under shade.

b. Collection of poultry waste from deep litter system Dry fiber free coir pith is spread as a layer to a height of 5 to 10cm on the floor of the poultry production unit. The birds are grown on this coir pith bed and the droppings are collected in the coir pith. After a period of three months, partially degraded coir pith containing poultry droppings and feathers are shifted to the compost yard and heaped under shade. c. Method of composting poultry waste with coir pith A known quantity of the poultry waste as collected above along with coir pith is inoculated with Pleurotus sajor-caju @ 2 packets per tonne of waste in order to speed up the composting process. This mixer should be placed under shade as heap. The moisture content of the heap should be maintained at 50 to 60%. Periodical turning must be given on 21 th, 28 th and 35 th days of composting. Another two packets of Pleurotus sajor-caju is to be added during turning given on the 28thday of composting. Good quality compost will be attained after 45thday of composting. The nutrient contents of the composts of poultry litter collected from caged system and deep litter systems are as below;

Points to be remembered

Value Animal manures especially poultry manure are rich in N and the nutrient value of the manure is reduced by loss of N through ammonia volatilization and denitrification. Good quality poultry manure can be obtained by mixing the poultry waste with selective carbonaceous material such as coirpith and inoculation with suitable microorganism. It can be used as an eco-friendly technique for the conversion of poultry waste into valuable compost. Benefits Poultry wastes contain higher concentrations of nitrogen, calcium and phosphorus than wastes of other animal species and the presence of nutrients provides more incentive for the utilization of this resource. The loss of nitrogen from poultry droppings can be effectively conserved by composting with coir pith and serves as a good source of organic nutrients to agricultural fields. To make the organic nutrients present in poultry waste available to plants, the waste has to be composted suitably to minimize the volatilization of ammonia. Applications This technology is widely suitable and applied to the poultry farmers to utilize the solid waste in an effective manner. The poultry waste compost will be a very good organic manure@6 ton / ha for all the crops. Limitations The uninterrupted availability of the raw materials has to be ensured for continuous production on a commercial scale. Source Mahimairaja,S., P.Dooraisamy, A.Lakshmanan, G.Rajannan, C.Udayasoorian and S.Natarajan.2008.Composting technology and organic waste utilization in Agriculture.A.E.Publications, P.N.Pudur, Coimbatore=641 041 www.fao.org |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Activities |

Organic Certification |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Marketing |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Home | Nutrient Management | Weed Management | Pest Management | Disease Management | Gallery | Contact | |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

© All Rights Reserved. TNAU-2008. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||