SEED HARDENING TECHNIQUES FOR DROUGHT TOLERANCE

Seed hardening techniques for dry land crops

The success of dry land agriculture depends on seasonal rains. Several management strategies are followed to enhance the production potentiality of the crop under rainfed condition. Seed hardening is one such seed management technique, where seeds are hydrated and then dried to their original moisture content to tide over the stress environmental condition at field. Though simple water acts as a good hardening agent, the efficiency could be enhanced by use of chemicals where selectivity depends on crop.

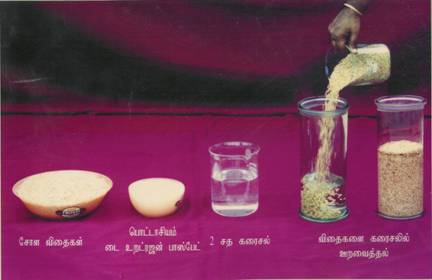

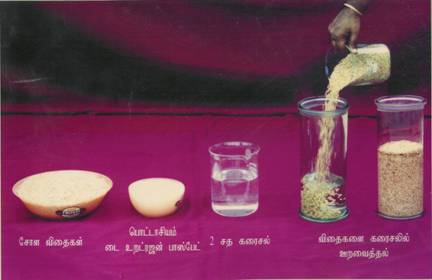

The seed hardening techniques recommended are as follows:

Crop: Pearl millet

Chemical and concentration: 2 % Potassium chloride

Methodology: Dissolve 20 gm of salt in 1000 ml of water. Soak 1 kg of seed in 650 ml of this solution for 10 hours and dry back to original moisture.

Crop: Sorghum

Chemical and concentration: 2% Potassium dihydrogen phosphate

Methodology: Dissolve 20 g of salt in 1000 ml of water. Soak 1 kg of seed in 650 ml of the solution for 16 hours and dry back to original moisture or weight.

Crop: Cotton

Chemical and concentration: 2 % Potassium chloride

Methodology: Dissolve 20 g of salt in 1000 ml of water. Soak 1 kg of seed in 650 ml of the solution for 10 hours and dry back to original moisture or weight.

Crop: Sunflower

Chemical and concentration: 2 % Potassium chloride

Methodology: Dissolve 20 g of salt in 1000 ml of water. Soak 1 kg of seed in 650 ml of the solution for 12 hours and dry back to original moisture or weight.

Crop: Pulses, black gram, green gram

Chemical and concentration: 100 ppm Zinc sulphate, 100 ppm Manganese sulphate

Methodology: Dissolve 1000 mg of salt in 1000 ml of water. Soak 1 kg of seed in 350 ml of the solution for 3 hours and dry back to original moisture or weight.

Cost of treatment: Rs.0.50 Kg -1

The percentage of yield increase: 10-15 %.

Source: TNAU, Coimbatore, 2007

Designer seed technology

The designer seed technology has been developed for cotton, black gram and for direct sown paddy. It is an integrated seed treatment method which involves addition of nutrients and plant protectants to the seed for improved emergence and establishment.

a. Cotton

The acid delinted cotton seeds are mixed with polykote @ 3 g by diluting in 5 ml of water followed by Carbendazim @ 2 g / kg + Imidachloprid @ 5 g / kg + Pseudomonas 10 g / kg + Azophos120 g / kg in sequential manner.

The treated seeds recorded 12 per cent yield increase over control. The cost benefit ratio of this is 1: 1.6.

b. Black gram

For irrigated ecosystem, an integrated seed treatment viz., fortified seed + polykote @ 3g + dimethoate @ 5ml + bio-inoculant (Trichoderma viride) @ 4g+ Rhizobium @ 20 g + Azophos @ 40 g / kg of seed ) could be recommended for rainfed ecosystem. The yield increase realized is 16.8 per cent. The cost benefit ratio of this treatment 1: 3.6.

For rainfed ecosystem, the seed treatment viz., Hardened seed + polykote @ 3g + dimethoate @ 5 ml + Trichoderma viride @ 4g + Rhizobium @ 20g + Azophos @ 40g + coating with 2 % Mg CO3 / kg of seed registered higher physiological seed quality attributes and increased yield of 66 kg /ha.

The yield increase realized is 15 per cent. The cost benefit ratio of this treatment 1: 3.6. The cost benefit ratio was of 1:1.6.

Direct sown rice

The rice seeds were fortified with KCl (1%) for 16 h, followed by sequential coating with polykote @ 5g Kg-1+ Carbendazim @ 2 g Kg-1+ Imidachloprid @ 5 ml Kg-1 + Pseudomonas fluroscens @ 10g Kg-1 + Azophos @ 120g Kg-1.

The treated seeds recorded 14 percent yield increase over control.

Source: TNAU, Coimbatore, 2007

Seed pelleting

It is the process of the packaging the seed with sufficient inert materials and active ingredient in order to improve the seed size, shape and weight in order to enhance the seed performance and seed handling characteristics.

Pelleting technology has been standardized for mustard hybrid seed through private funded project on “Priming and pelleting for value added seeds”. The technology is proposed for obtaining PATENT during current year.

The innovated technology provides optimized composition of pelleting mixture for achieving optimum speed and percentage germination. It also gives sufficient pellet strength to withstand transport and handling.

The cost of the treatment is Rs. 500 Kg -1

Source: TNAU, Coimbatore

Seed priming

Seed priming is the process of controlled hydration of seeds to a level that permits pre-germinative metabolic activity to proceed, but prevents actual emergence of the radicle. It enhances the germination percentage, speed and uniformity of germination, improves the resistance towards water and temperature stress and increases the shelf-life of seeds.

The technology has been standardized for few commercially important vegetable crops viz., tomato, brinjal, chillies, onion, beetroot, bhendi, radish and mustard. Seed priming was found to improve initial seed germination as well as storability of seeds. The overall improvement in germination over control was 24 to 40 per cent both initially and after six months of storage.

Application for obtaining Patent has been filed for the priming technique developed for mustard hybrids through Private funded project “Priming and pelleting for value added seeds”. The cost of the treatment is Rs. 500 Kg -1

Source: TNAU, Coimbatore

Polymer seed coating

Seed coating is the process of coating the seeds with polymers of different colours for enhancing the seed germination, seedling vigour and field establishment. Seed coating has improved the germination by 14 percent and seedling vigour 23 percent with the evaluated eight crops.

Influence on seed germination and seedling vigour

Crop |

Seed germination % |

Seedling vigour |

Polykote |

Control |

Polykote |

Control |

Paddy |

88 |

75 |

2442 |

2168 |

Maize |

98 |

92 |

4484 |

3766 |

Sorghum |

92 |

78 |

3717 |

2419 |

Bajra |

98 |

88 |

3377 |

2728 |

Soybean |

92 |

79 |

3373 |

2307 |

Sunflower |

92 |

71 |

3690 |

2212 |

Tomato |

92 |

79 |

1555 |

937 |

Bhendi |

96 |

82 |

2967 |

1851 |

The known quantity of polymer will be mixed with known volume of water and coated on the surface of the seed manually. The colour and dose of polymer is crop specific.

Crop |

Treatment details |

Colour of polymer |

Dose of polymer(g/kg) |

Volume of water (ml) |

|

Paddy |

Yellow |

3 |

5 |

Paddy |

Maize |

Pink |

3 |

5 |

Maize |

Sorghum |

Pink |

3 |

5 |

Sorghum |

Source: TNAU, Coimbatore |